MECSPE 2026 – BOLOGNAFIERE

2026 kicks off with a must-attend event for all industry professionals: MECSPE 2026, the leading trade fair for technological innovation and advanced solutions in the

2026 kicks off with a must-attend event for all industry professionals: MECSPE 2026, the leading trade fair for technological innovation and advanced solutions in the

When raw materials and technology meet: VARO and TECNOFIL together Bringing together the expertise of a wire manufacturer and a machine builder for wire processing

Introducing VARO SmartHelp: our new support package SmartHelp is not just a service, but the result of over two years of work, intensive testing within

We started the year off on the right foot: an afternoon devoted to innovation, technology and people-to-people discussions.The first meeting of VARO FORWARD allowed us

In VARO, this time of year represents a significant moment.After months of work, planning, and production activities, many machines are now ready to reach their

An intense and stimulating week in Poland came to an end, during which hundreds of kilometers were traveled and 13 customers were met in different

Our sales managers recently visited Finland to meet with local customers and partners, consolidating existing relationships and establishing new ones. During the tour, they had

Where Artificial Intelligence and Augmented Reality meet to revolutionize the way we work.A project designed to make technical support more immediate, immersive, and collaborative, putting

Three days in which the industry moved together, between technologies on display and moments between booths. Thanks to those who met with our Lucio Bussani:

Some of you have already had the chance to peek at our spaces during visits, but today we can finally say that they are completed

In VARO ‘s assembly department, design ideas become reality: it is here that the components made in the different departments are integrated, shaping complete, ready-to-use

For us at VARO, human contact is not just a value: it is part of our philosophy, it is what defines and guides us every

In September, VARO will be taking the stage on three continents.From Africa to the United States, all the way to Southeast Asia: our technology travels

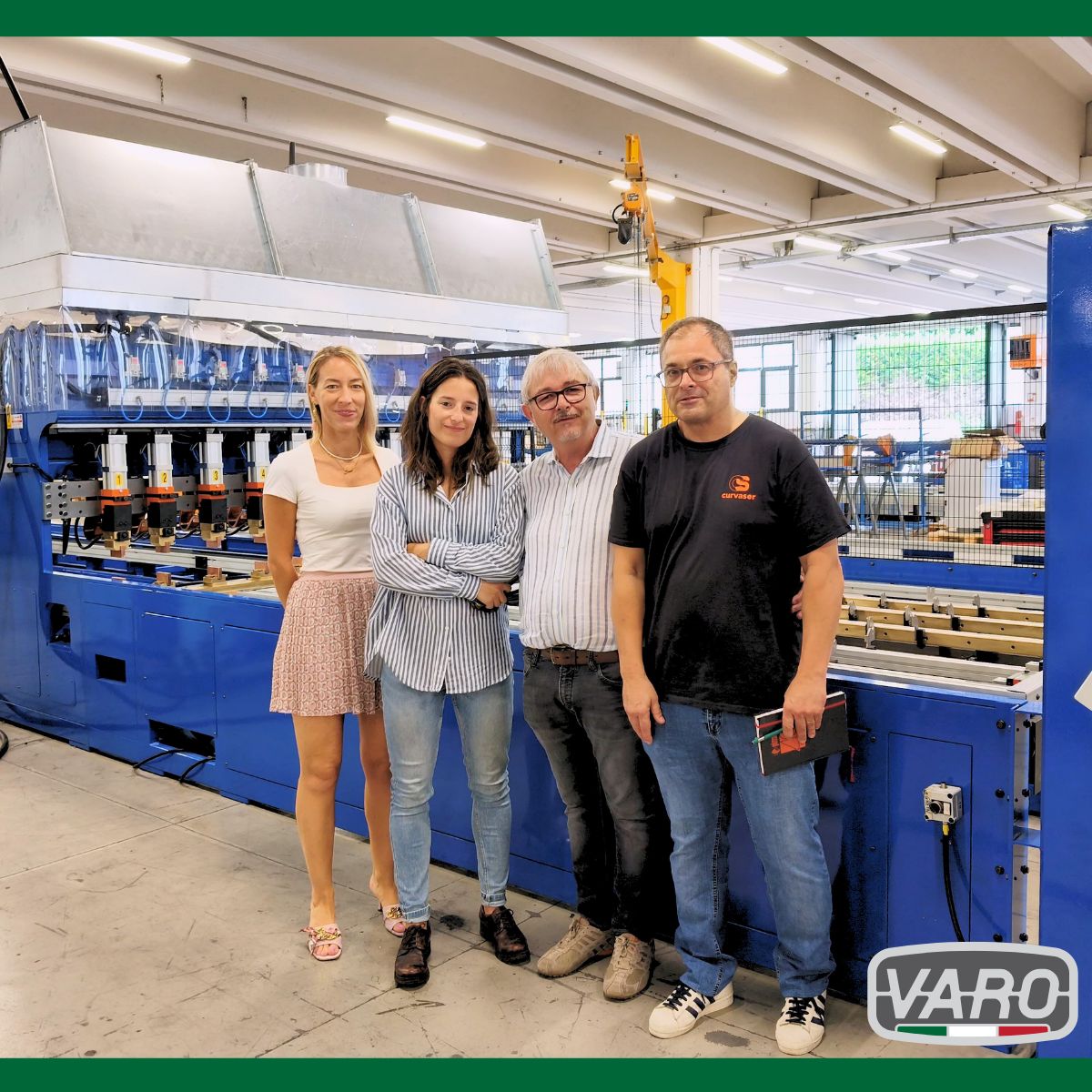

We had the pleasure of hosting in Varo the team from Metalmalla, who came from Spain to closely follow the FAT of their new machines.

We had the pleasure of hosting in the company Paweł Węglarz, new salesman of Dig Switala Sp. z o.o. , our long-standing and trusted partner.Together

Every installation we complete tells more than just a finished job: it tells of a team’s commitment, attention to detail, and ability to transform technical

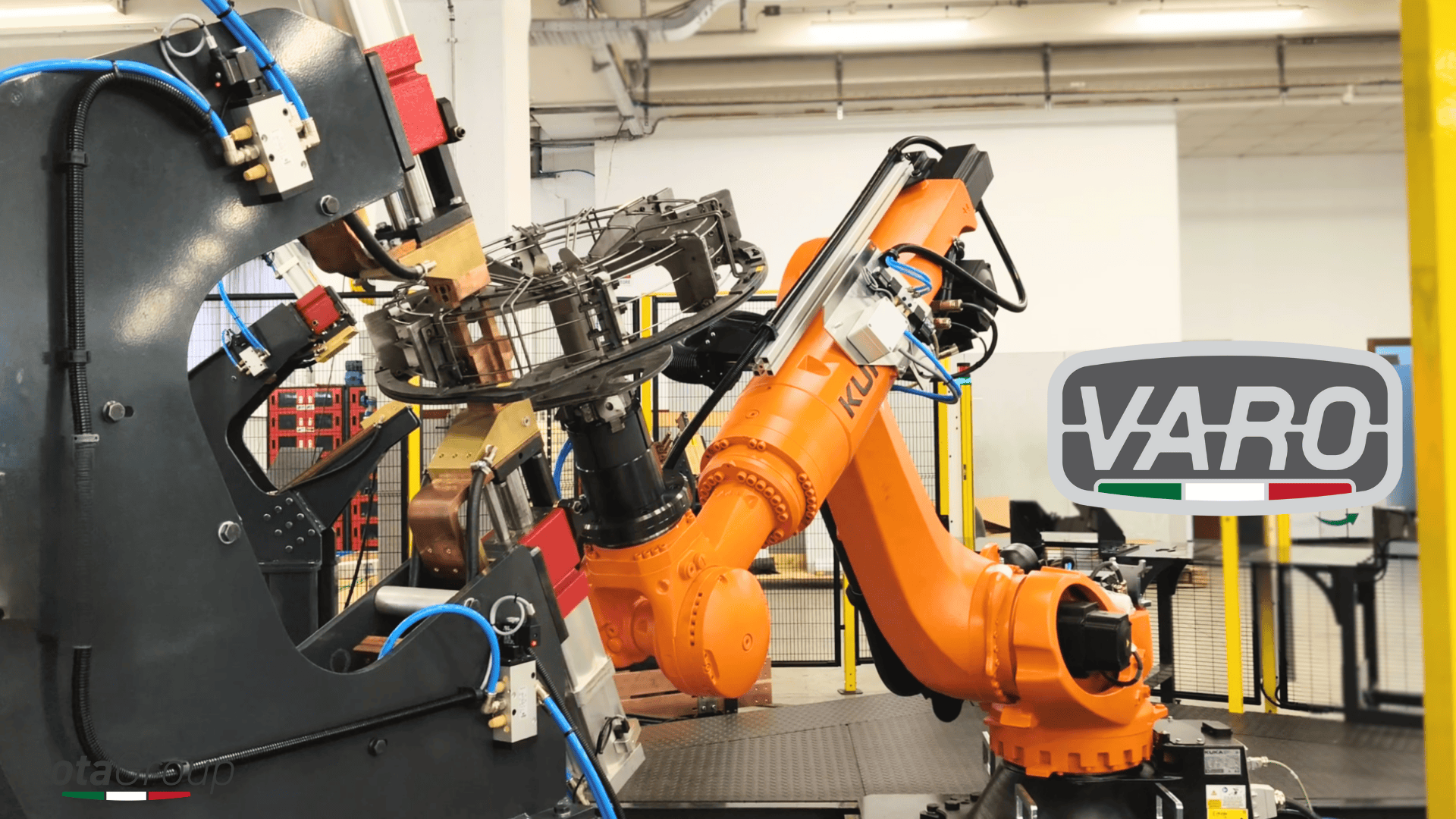

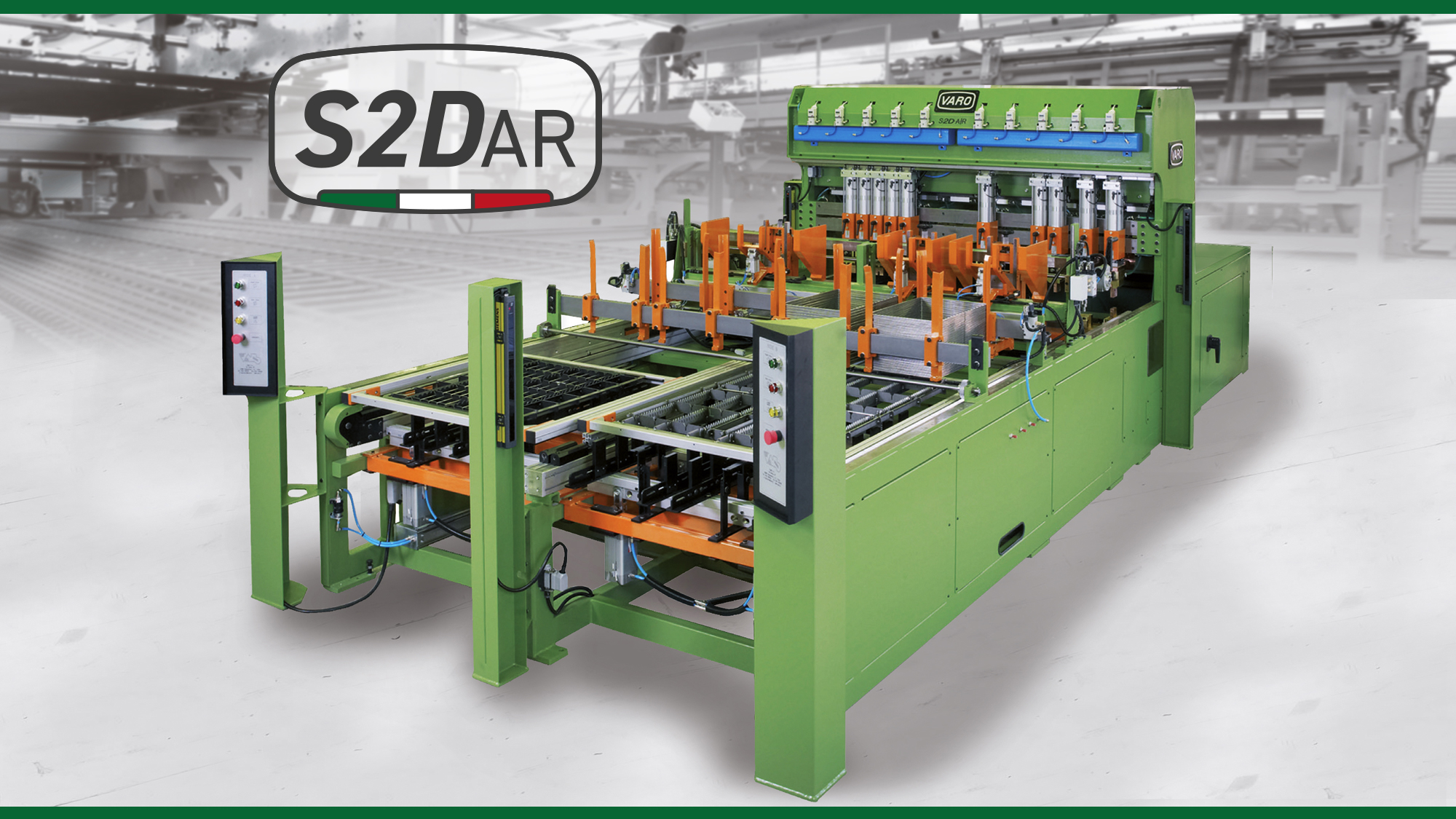

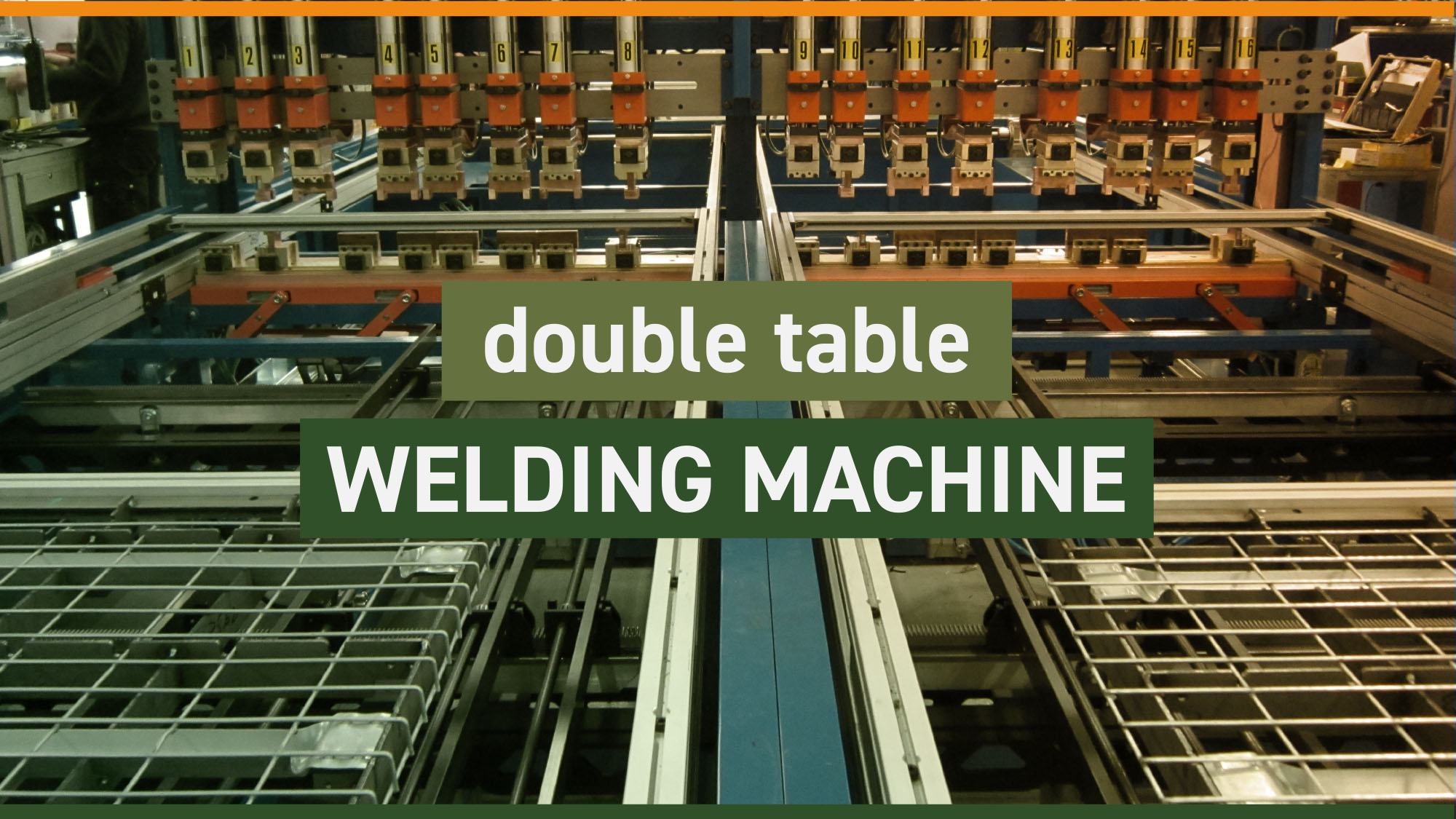

Efficiency and flexibility in automatic welding It is a solution designed for those who need to automate welding with a flexible and reliable system. Thanks

Abbiamo avuto il piacere di ospitare in azienda Cargo Pak srl, nostro stimato cliente, per il collaudo della loro saldatrice semiautomatica S-2D A/R.Questa macchina a

These were intense days, full of meetings, exchanges and curiosity around our machines.We want to thank everyone who came to visit us: it is always

We had the pleasure of hosting DUMAT, who came to our facility to witness the testing of their new SARG, accompanied by our long-time Polish

Whether it’s shopping carts, clotheslines, or other seemingly common products, every project hides unique challenges. That’s where we come in: we turn real problems into

From May 6 to 8, we’ll be in Monterrey, at Cintermex, for the 2025 edition of Fabtech Mexico. It’s a great opportunity to explore the

After months of intensive design, development, and testing, we have successfully concluded the testing of a highly customized plant, developed from the ground up to

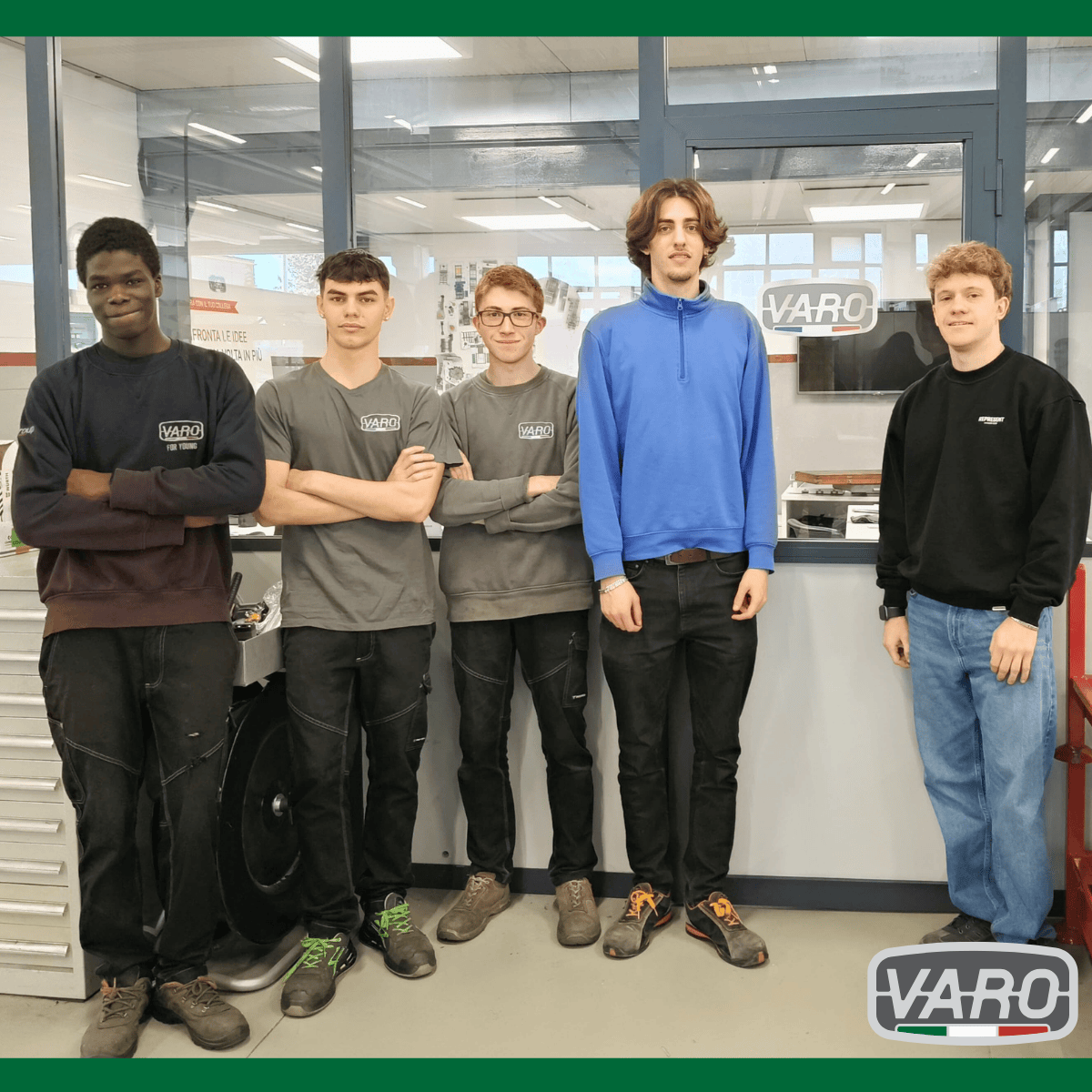

In VARO, we believe in the value of training and in the role that companies can play in the development of young talent.For this reason,

Designing is our business: For over forty-five years, at VARO we have been designing and manufacturing wire processing machines, with a special focus on automatic

VARO at STOM 2025 – Let’s meet in Kielce We are excited to announce our participation in STOM 2025, the prestigious international trade fair dedicated

Innovation, efficiency and precisionIn the wire processing industry, innovation is the key to efficiency, precision and versatility. Modern CNC (computer numerical control) bending machines have

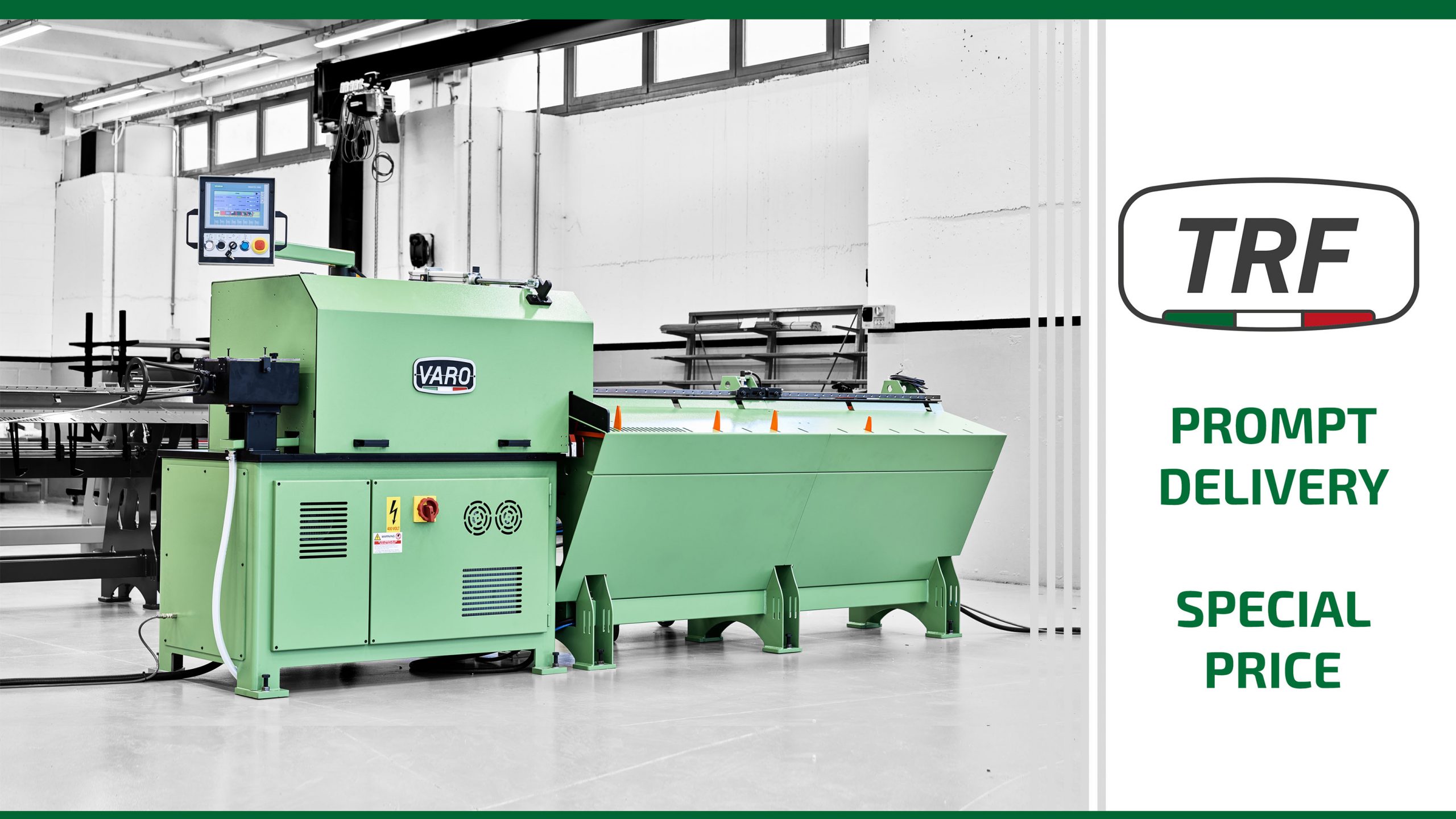

VARO ‘s TRF is a state-of-the-art wire straightening and cutting machine designed to ensure high processing speed without compromising accuracy. By combining advanced mechanics and

From February 11-13, 2025, Varo will participate in the Wire & Tube Mexico trade show, which will be held at CINTERMEX – Centro Internacional de

A STEP TOWARD MORE EFFICIENT MANAGEMENT AND STATE-OF-THE-ART LOGISTICS! With great excitement, we celebrate a milestone in VARO’s history: our Logistics department is now 100%

From Nov. 14-16, 2024, Lariofiere Como Lecco in Erba will host the 17th edition of the National Orientation, School, Training, University and Job Fair, one of the most anticipated events for those looking for a future in the world of education and work.

A machine designed to take welded mesh production to a whole new level

VARO machines are the productive core of many industrial sectors and the most important players have chosen VARO to make their own high quality productions.

SARG TURBO is the latest automatic welding machine produced by VARO. It was unveiled at WIRE 2024 and has been met with great success

VARO will be present at the most important international trade fair in the sector to present the latest innovations created for metal wire processing.

2024 for VARO began with an eye towards its reference markets in the world, to better understand the needs of existing and potential customers, to consolidate the areas where the company is already present and to explore new areas in where VARO machines can contribute to a leap in quality in metal wire processing.

Industry 5.0 represents the latest frontier of industrial evolution, characterised by close collaboration between humans and intelligent machines.

WIRE Mexico 2024 is the most important Central American trade fair in the

sector and VARO will be present to present the latest innovations created for metal wire processing.

In response to the needs of the manufacturers of heating units, VARO has created ad-hoc solutions for automated system fan covers.

VARO has a wide range of technical expertise: mechanical design, electronic design, custom software programming as well as all the necessary skills for the construction of special machines that integrate these skills in a synergetic manner.

The year 2017 was a turning point for VARO, during which the lines of development for the next 5 years were drawn, characterised by investments, expansion of space, strengthening of the various departments and increase in production capacity.

In the course of the years, VARO has established itself as a specialized machinery manufacturer for the creation of custom lines for products dedicated to the white goods sector.

The year 2017 was a turning point for VARO, during which the lines of development for the next 5 years were drawn, characterised by investments, expansion of space, strengthening of the various departments and increase in production capacity.

The welding machine designed for the production of mesh fences, modular fence panels, electro-welded panels, notched panels, in-line 3D folding and a lot more.

When the need for high production also requires extreme flexibility in use and set-up at the same time, VARO’s answer is the double table S-2D A/R welding machine.

Design, Supply chain and Production: 3 cornerstones of Made in VARO, managed and organised by 3 people who grew up in VARO.

ROTA Group, VARO and OMCG will be present at INTERWIRE Atlanta and at FABTECH Mexico City: two appointments to present the latest innovations in metal wire processing.

Lucio Bussani and Emanuele Pozzi, VARO’s sales team, talk about an intense 2022 under the commercial aspect.

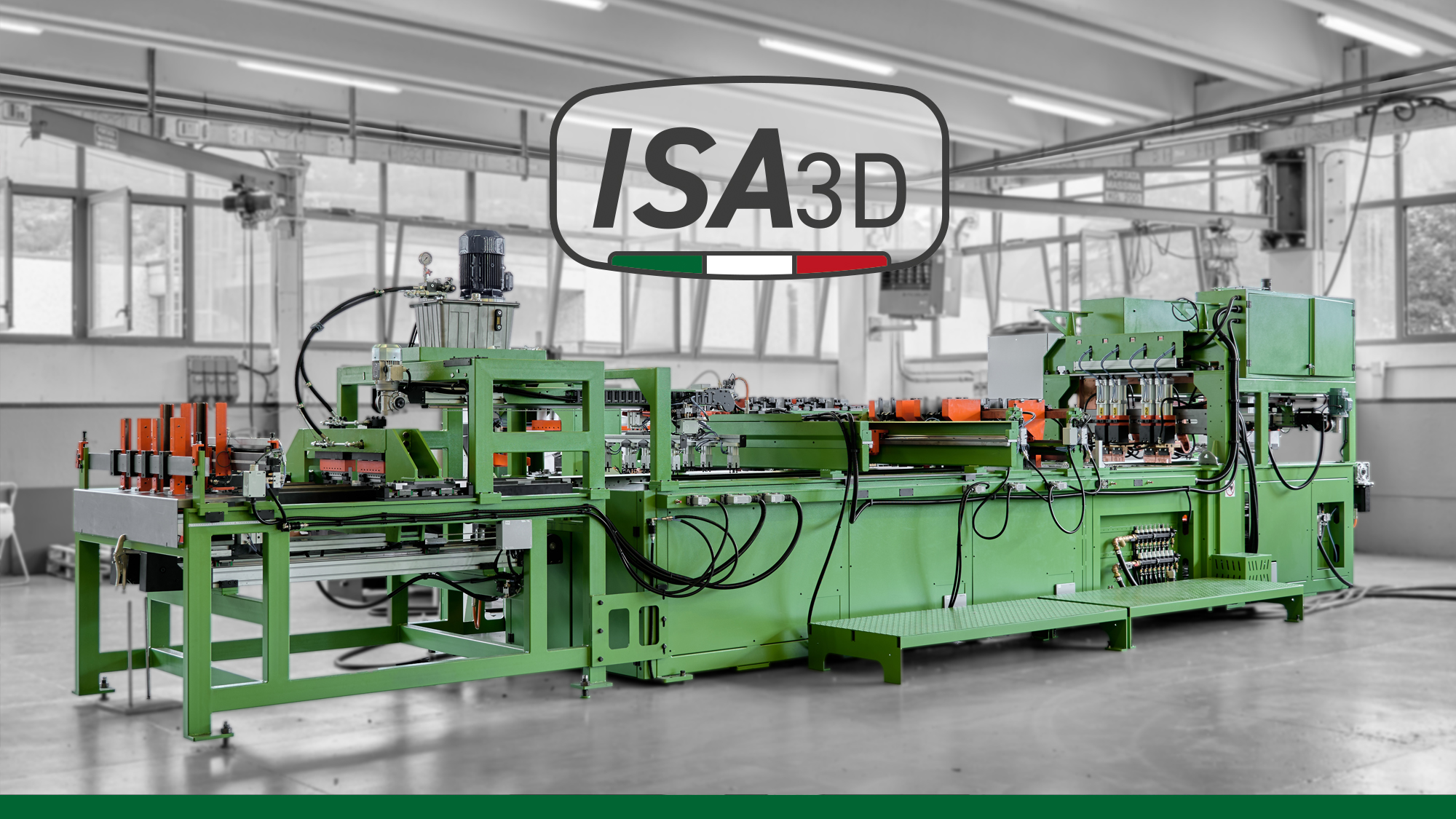

ISA 3D is a high-tech system, extremely versatile and suitable for creating a wide range of medium/light meshes and gratings.

Varo’s participation in WIRE SouthEast 2022 was a big success! A huge thank you goes out to ITA and ICE – Agencies that work to promote and internationalize Italian enterprises abroad.

WIRE South East Asia 2022 is the most important Asian fair in the sector and VARO will be there to present the latest innovations made for wire processing.

The current scenario in which Italian companies operate is characterized by a dizzying increase in energy costs, raw materials and components, with supply difficulties as well.

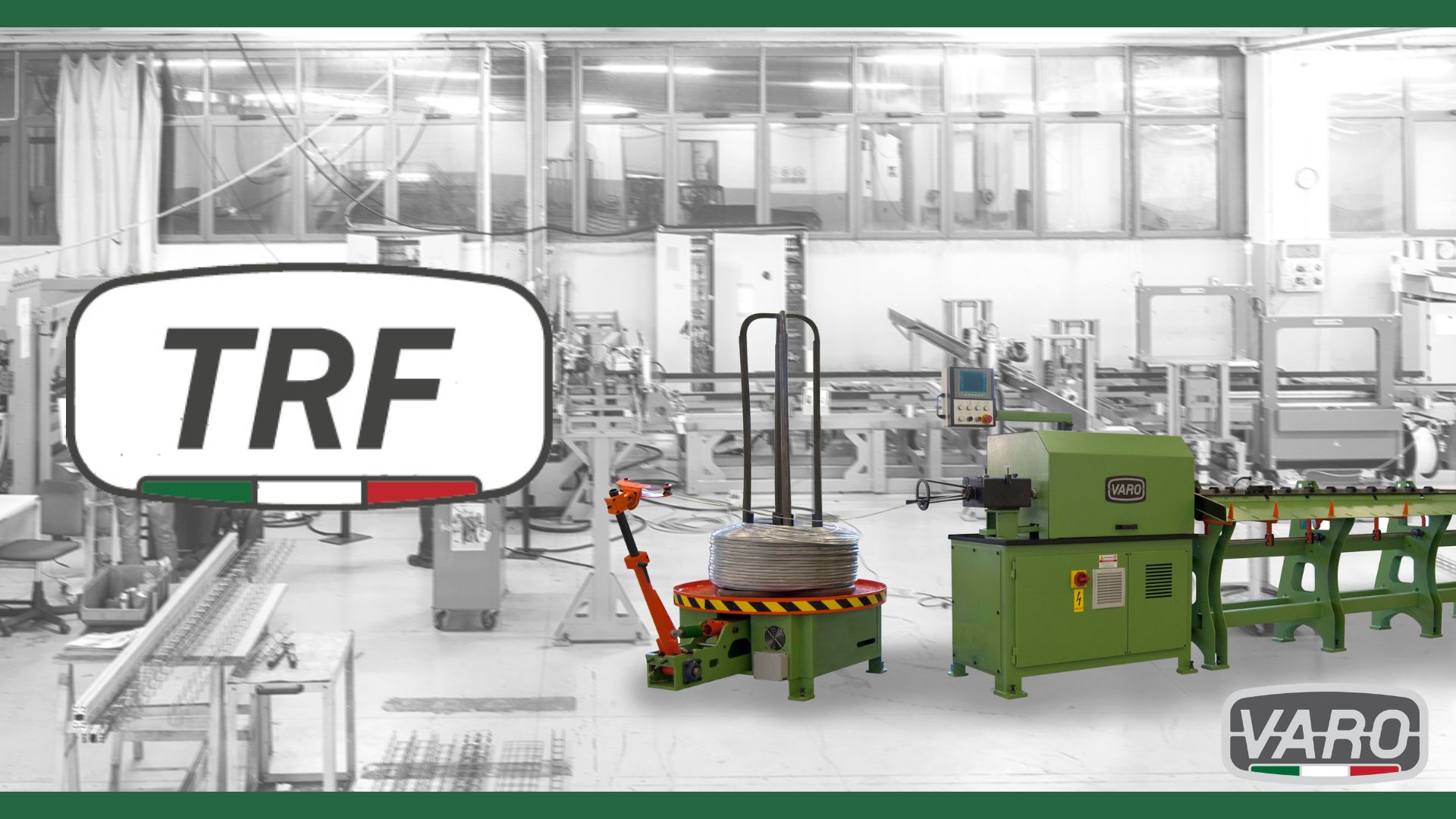

Industrial Technology, the international magazine focused on machines, plants, components, automation, plastics, industry 4.0, steel, talks about VARO and the success of the TRF

VARO will participate in the most important international fair in the sector to present the latest innovations made for metal wire processing.

RotaGroup, already owner of VARO, has recently expanded the offer of machines for metal wire processing with the acquisition of OMCG Italia srl.

Experience and knowledge acquired over the course of over forty years of activity allow VARO to design and build special lines in response to specific production needs.

Investments, consolidation, expansion, development, optimization: these are the keywords that indicate the direction taken by VARO for 2022.

VARO presented a new specialized department in October 2021: VARO TRF (VARO STRAIGHTENING & CUTTING DEPARTMENT – CUTTING AND STRAIGHTENING DIVISION)

Varo has accepted the digital challenge in manufacturing world and has integrated know-how and new digital skills within the classic production paradigms: My Varo is the tool that puts into practice the concepts promoted by Industry 4.0.

VARO will participate in the 2021 edition of the INTERWIRE fair, at the Georgia World Congress Center, on 26 and 27 October

A solid partnership that since 1997 has been synonymous with high professionalism: Curvaser, VARO’s exclusive partner for Spanish market.

One of the leading and most representative products of VARO offer is the TRF straightening & cutting machine.

VARO continues to develop its network of international partnerships, to be closer to their customers, all over the world.

In addition to the recognized performance of the VARO machines, what further differentiates the Valmadrera company is the efficiency of the service.

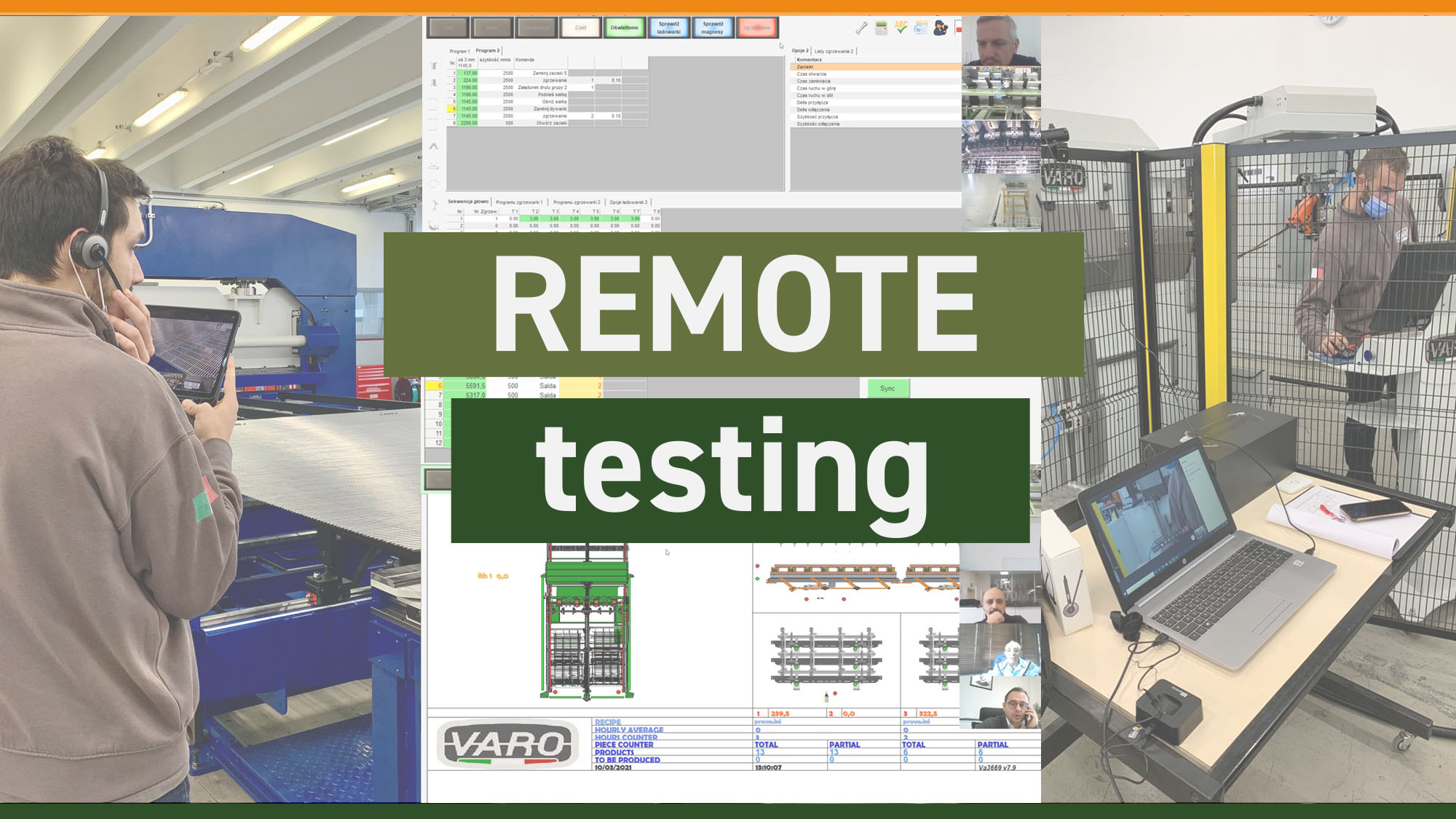

Remote testing reduces management times and costs, bridging the gap between VARO and its customers.

VARO continues to develop its network of international partnerships, to be closer to their customers, all over the world.

The difficulties encountered at a global level during 2020 have not changed the approach of Varo in recent years. Varo keep focusing on R&D, continuous technological investments and global commercial expansion.

The new welding machine designed by VARO makes a further advance in the direction of maximum flexibility in production and reduction of setting times.

VARO has undertaken a process of total company’s modernization for several years in order to design/produce increasingly cutting-edge machines, optimizing production and improving quality

The new welding machine designed by VARO makes a further advance in the direction of maximum flexibility in production and reduction of setting times.

We are developing a network of international partnerships to be closer to our customers and to provide an even better service

Double table welding machine: our solution for the need of high productivity and maximum flexibility in production.

The market requirements push us to develop specific technologies to perform particular processes: here is our module for in-line notching.

Thanks to our production process that it’s managed for the most part internally, we can give an immediate feedback to our customer’s requests.

The integration of digital tools and services to make the experience of using Varo machines more complete and detailed.

© 2023 Varo S.r.l. Unipersonale | Tutti i diritti riservati – P.IVA: 00808860134 – Leggi l’informativa sulla privacy – Cookie Policy | intenso.it