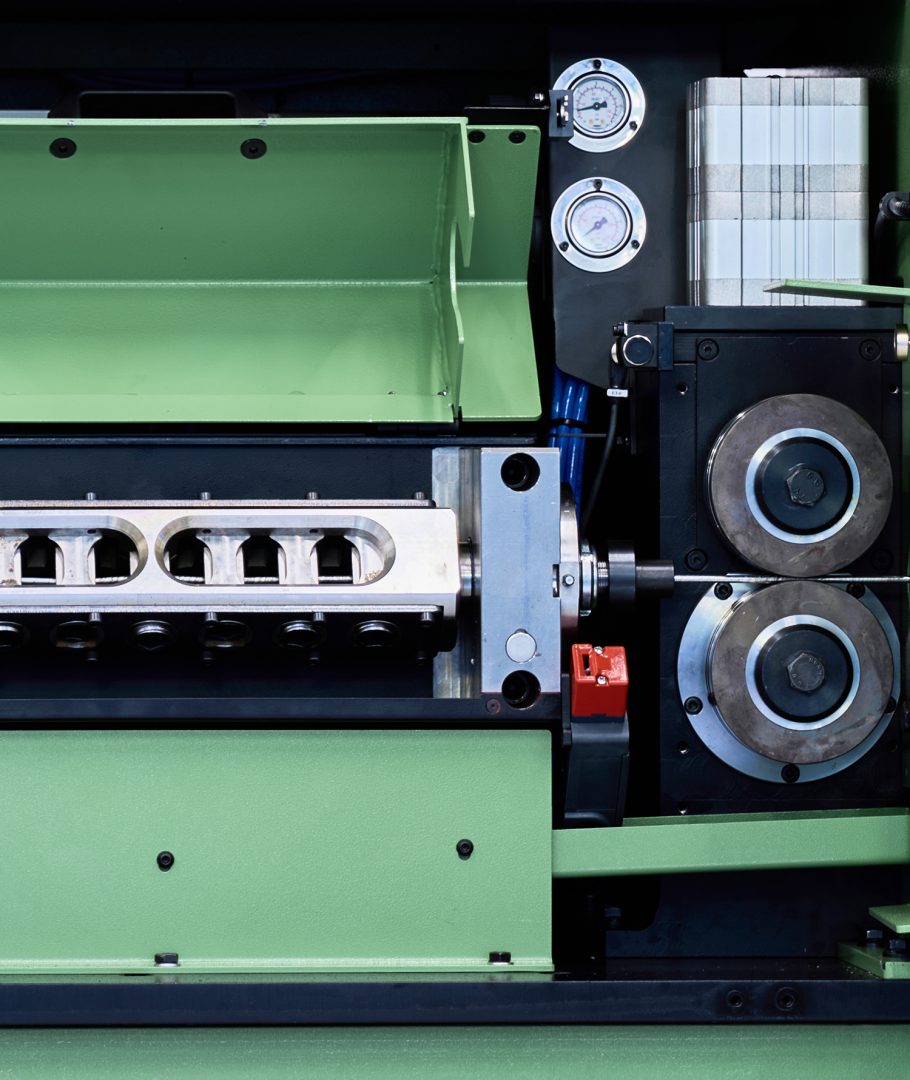

The market requirements push us to develop specific technologies to perform particular processes: here is our module for in-line notching.

Meshes notching process is common when it comes to trimming, while the creation of openings made directly in line is not so conventional.

Varo in-line notching primarily responds to the high productivity needs of the manufacturers of animal cages intended for breeding or for the pet world.

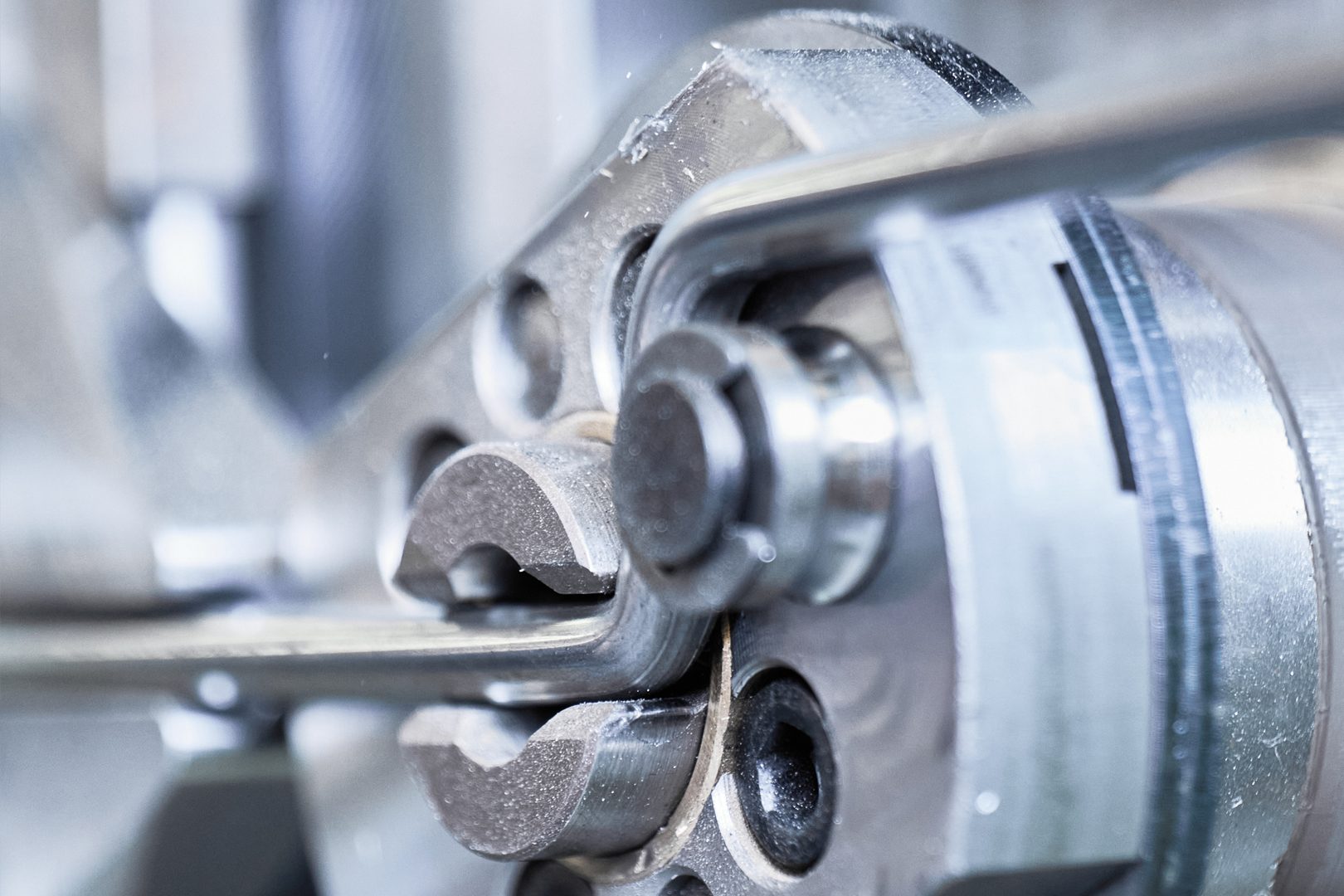

The complexity of this process consists in the high productivity obtained from in-line processing, combined with the high cutting precision.

Notching is performed on one or more units, depending on the complexity of the final product.

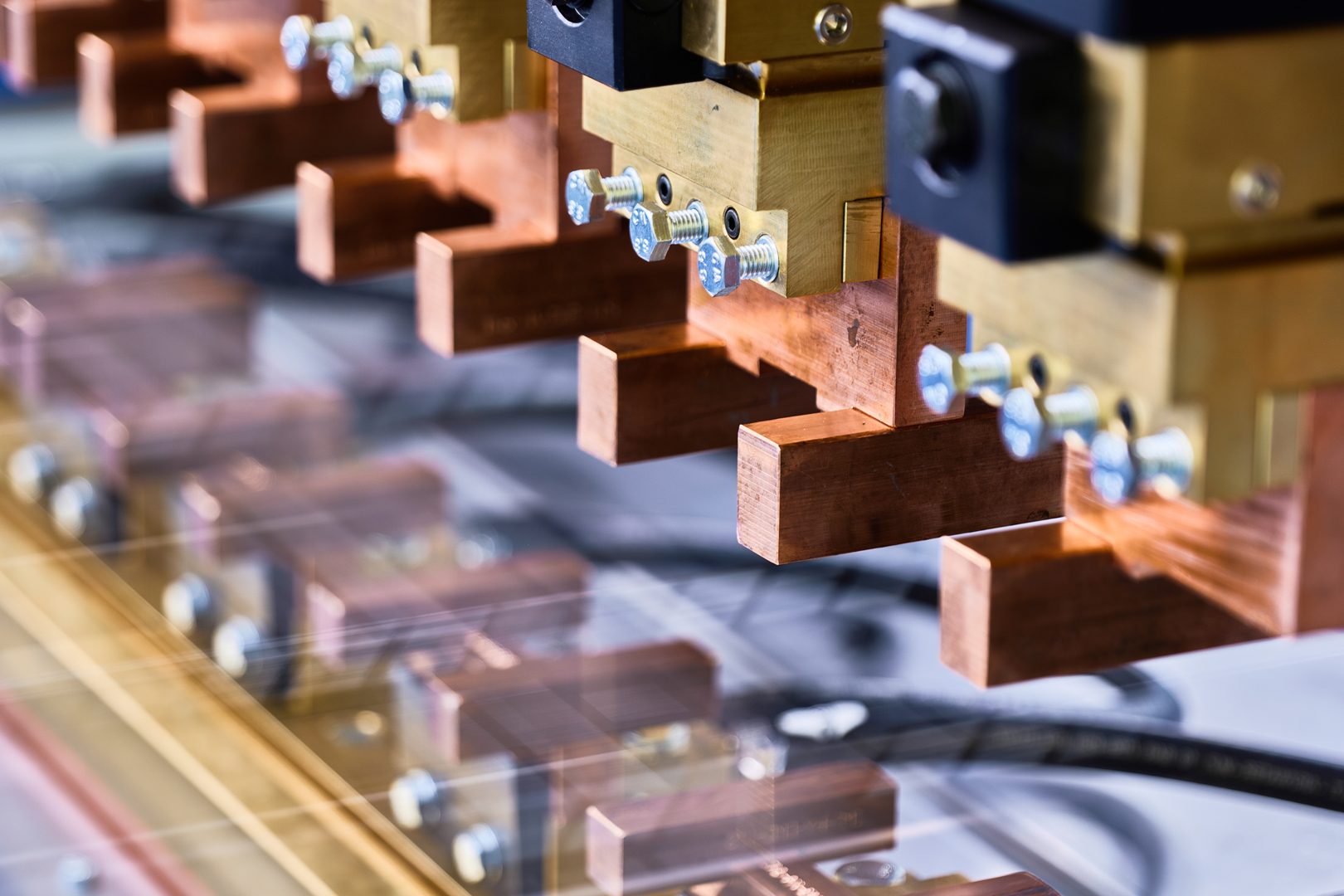

The application of these units on a SAR machine allows to achieve a high level of productivity and complexity, while ensuring unique accuracy.

A SAR machine equipped with notching units works in an automatic cycle by taking the longitudinal wires from a series of rolls and taking the cross wires – that are fed into pre-cut and straightened bars – from an automatic loader.

Notching is performed in-line and the setting is performed with one single operator panel.

We are partners of our customers and together with them we produce new solutions, to meet their needs of greater productivity, greater customization, with quality and reliability always at the highest level.