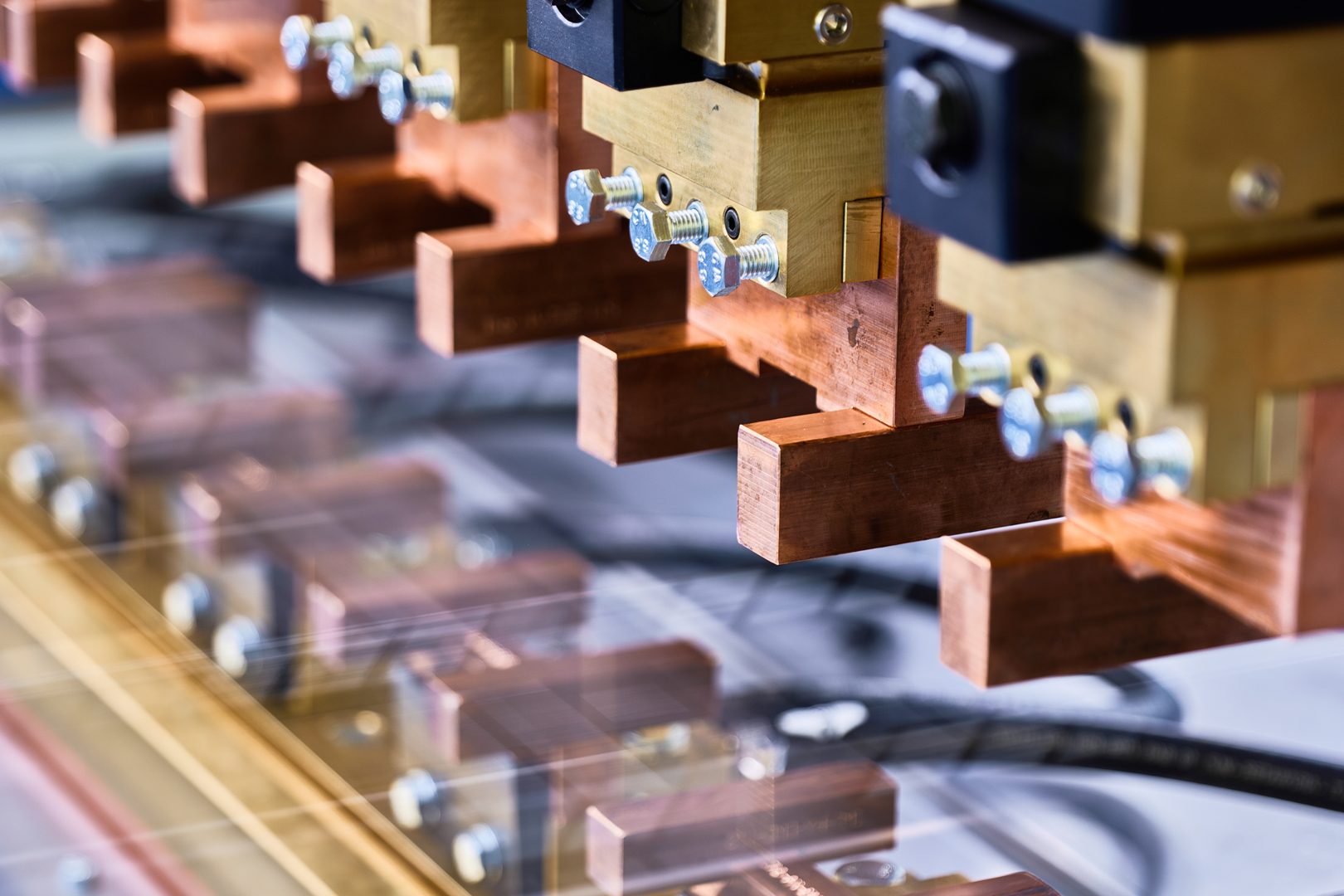

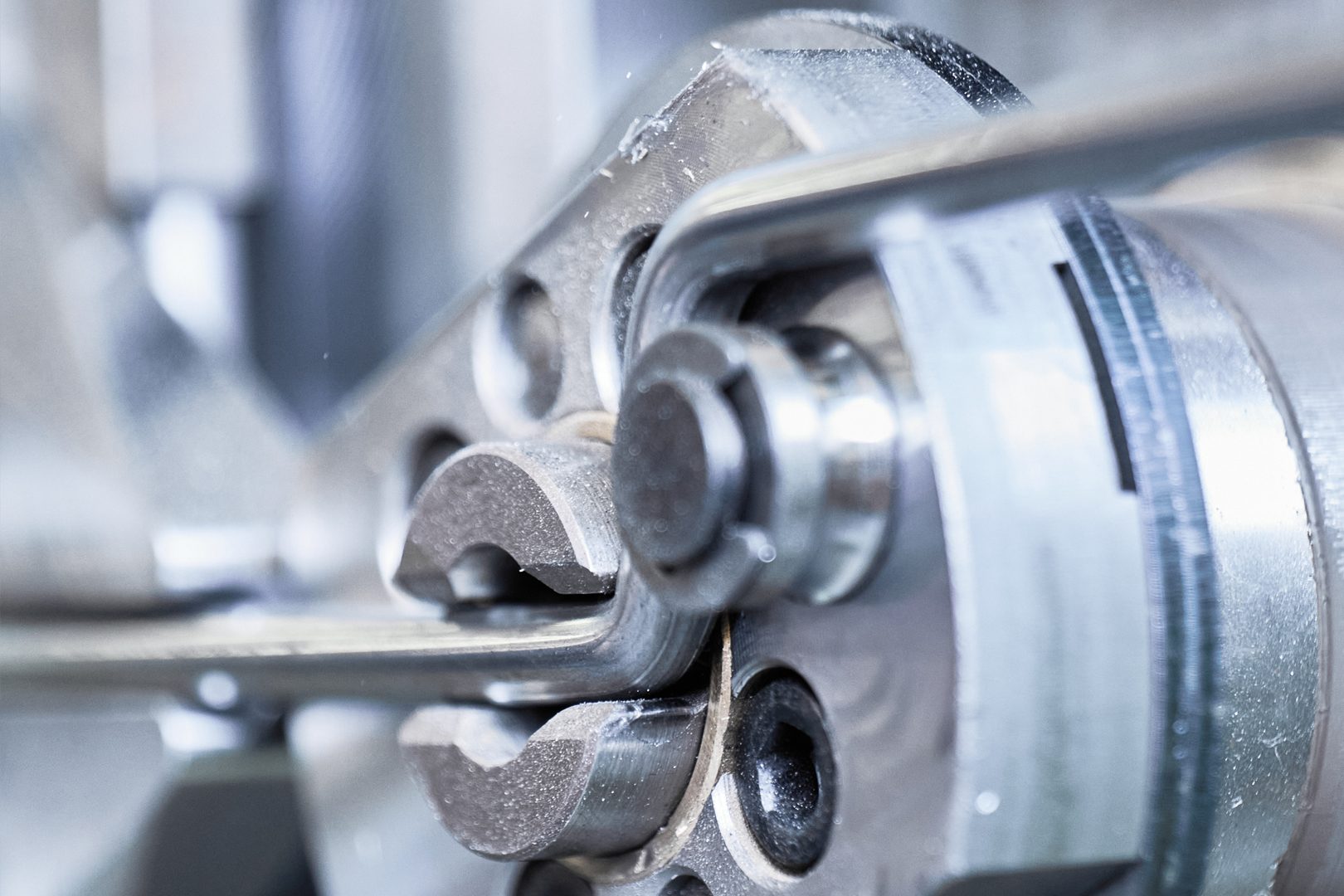

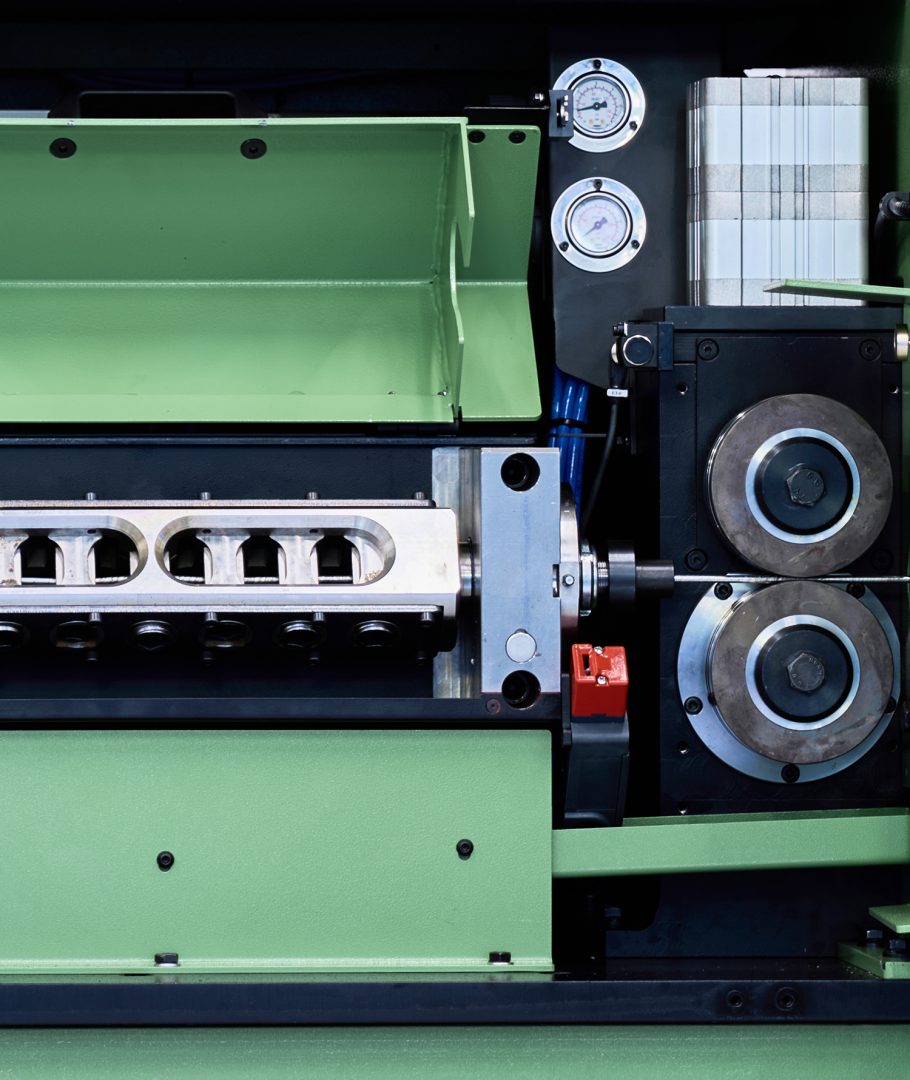

15,000 kilograms of steel, 12,000 meters of electrical, pneumatic hydraulic connections, a personal computer as brain and 1200 hours of passion for our work: from this VARO starts to create a SARG 2500, the welding machine which concentrates all the best characteristics of our vision and our success in the market.

Thanks to the experience of a VARO’s customer, VARO is glad to present the services that complete the supply of an automatic welding plant, up to the beginning of production.

Reliability, productivity and flexibility are the goals that led YOTA LTD – Bulgaria – to purchase a new SARG 2500.

Starting from the customer’s target, VARO’s engineers and workers have designed and built a fully automatic SARG 2500 welding system with a very high production capacity.

In addition to the recognized performance of the VARO machines, what further distinguishes the Valmadrera company is the efficiency of the service.

If perfection lies in the details, it is equally real that in VARO no phase of the work is neglected and left to chance.

An exclusive team of technicians, specifically prepared for shipments, is dedicated to disassembling the line, packing each component and verifying the correct positioning of individual parts on the means of transport.

Despite the complexity represented by a fully automatic system, the difficulties related to recent health events have generated the need to review the assembly methods at the Bulgarian company.

Thanks to the excellent coordination between VARO technicians and YOTA technicians, the remote installation and testing of the system was successful. This new formula has laid the foundations for the complete review of the installation and start-up process. Further, this method of installation allows the customer technicians to know plant in detail and, above all, to significantly reduce installation costs.

In VARO, these last difficult months have been useful in reviewing some procedures without ever losing sight of the fact that each phase of the process conveys attention tout court to quality and the full achievement of customer satisfaction

VARO is always looking for new solutions to improve its service and its machines, to make them more efficient, performing, easy to use and long-lasting.