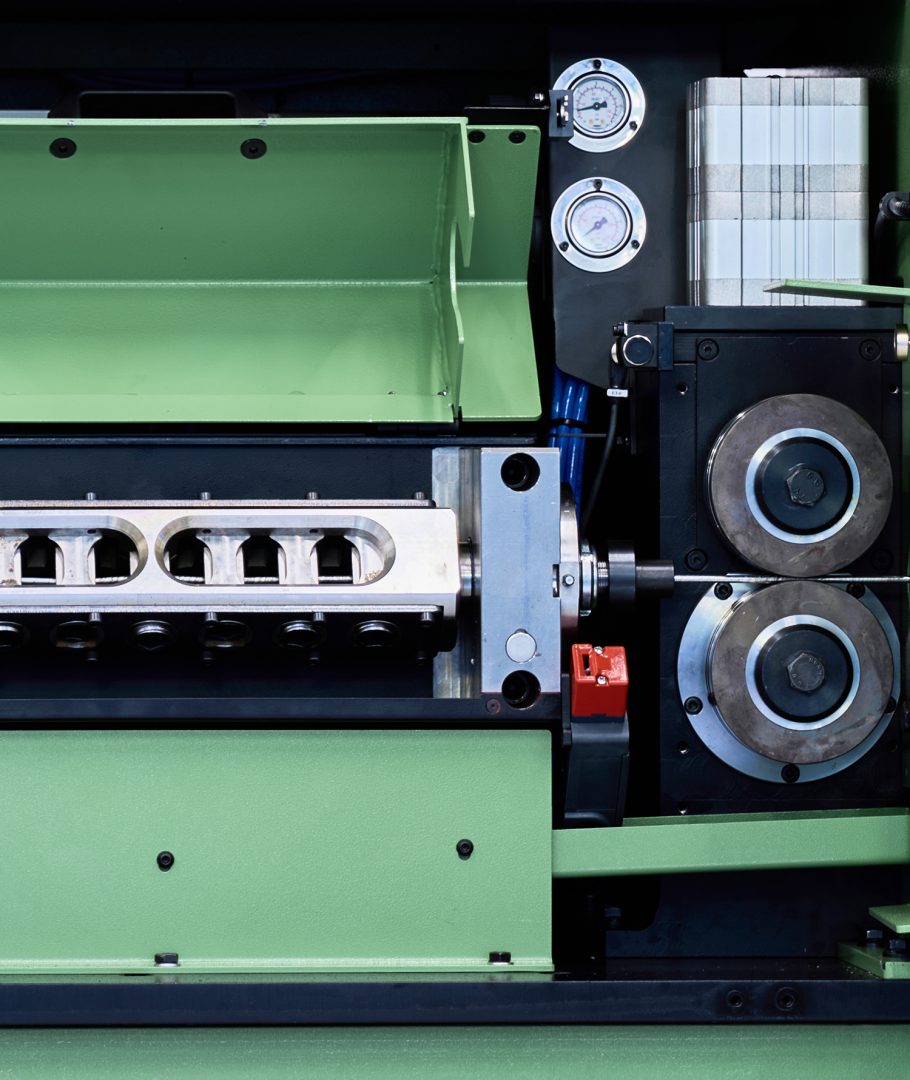

One of the leading and most representative products of VARO offer is the TRF straightening & cutting machine.

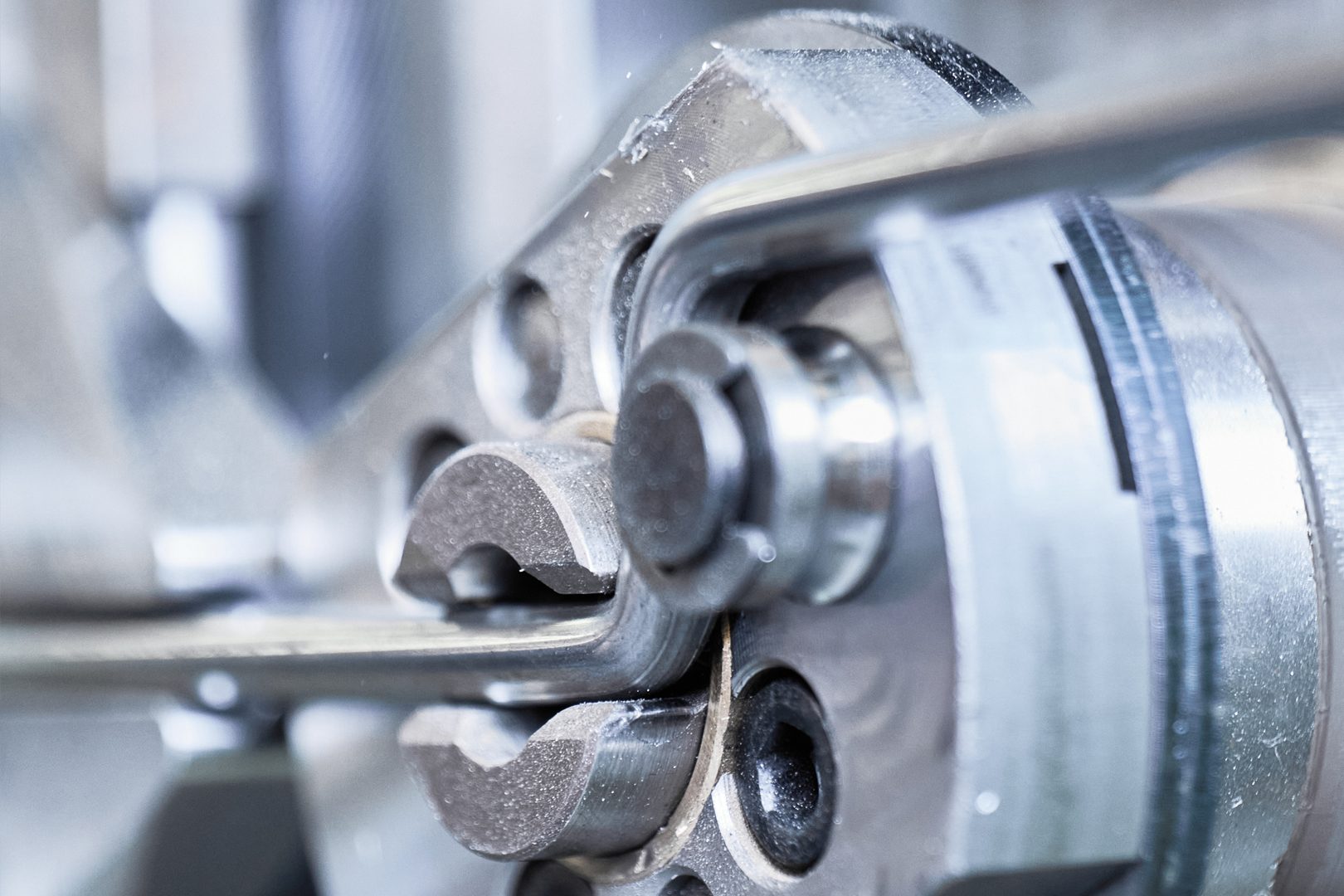

Sturdiness of the components, high performance and maximum reliability are the concepts that have guided its design.

To meet the market’s need for product supplies in a very short time, shorter response times are also required in the metal wire processing industry.

Aware of this need, VARO has given new impetus to batch production of TRF.

Thanks to an improvement in the internal organization of production processes, and to the optimization of costs and production times, VARO has been able to significantly reduce delivery times, coming close to providing the TRF model in a very short time. Sometimes, literally, ready for delivery.

TRF is the wire straightener that, in the 4.0 set-up, is able to provide all the necessary and relevant information about production trends as well as about the perfect functionality of the machine itself. All this, also available remotely and thanks to the new VARO APP application also on your mobile phone.

Thanks to the extreme proximity and close relationship with its customers, VARO has been able to introduce new and more performing technologies, guaranteeing a better and detailed control of production.

Mechanics and electronics of the TRF are combined to make it fast, reliable, easy to use and maintain and, above all, always precise. The interface placed on the machine has been developed to be as easy as possible to use and program by the operator.

The remote maintenance system makes it possible to detect, even remotely, the need for intervention and automatically communicates the operations to be performed for correct maintenance of the machine.

These remote operations are performed and coordinated exclusively by specialized and competent technicians.

Continuous monitoring of working conditions and process parameters

Sensitive machine data is detected during production, grouped according to the shift and according to the recipe, which can be consulted from the machine or remotely accessible. The information collected allows you to have a clear view of productivity:

- Alarm history

- Shifts history

- Recipe history

- Production history

The design in 4.0 logic and the components used make TRF VARO always connected: in order to have a complete diagnostic immediately available to the customer.

Reliability, efficiency, high performance are in TRF’s DNA.

TRF by VARO, thanks to its high productivity and maximum reliability, was able to quickly become one of the main and appreciated references in its product category.

Quick setup times, simple and intuitive interface and standard equipment among the most complete in its category. All this has allowed TRF to establish itself on the market as the best solution for the production of cut wire bars.

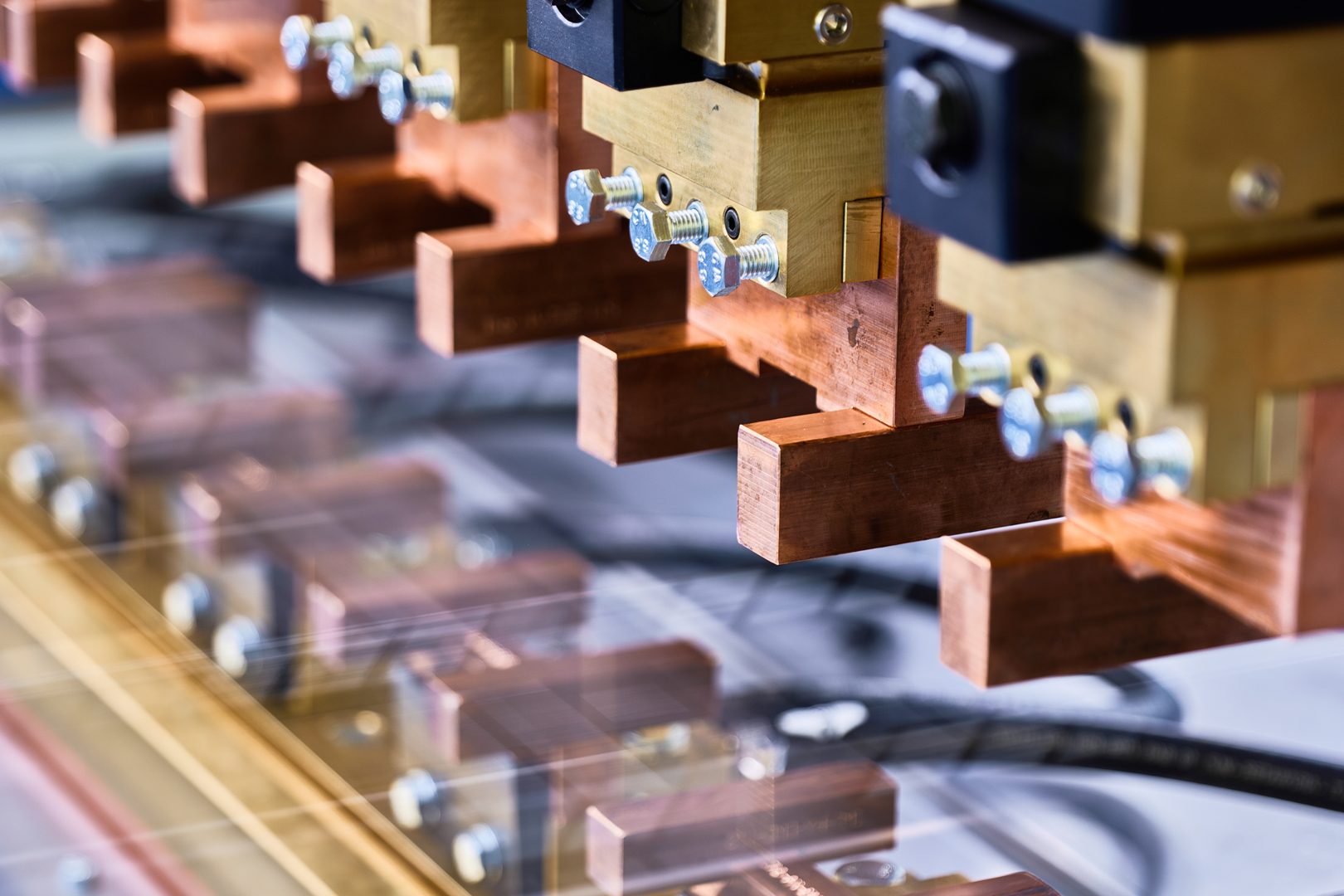

- complete equipment for 3 wire diameters (dragging guides, cutting unit, wire straightening bushes)

- reel and straightening rotor with variable speeds and electronically controlled by the machine

- mechanical stops for checking the cutting length

- feeding with reels from 12 to 30 Qt

TRF VARO can be customized both in terms of aesthetics and in the length of the counter and can be combined with dedicated accessories to increase its capabilities and realization possibilities. Among the most popular options, VARO offers the beveling machine (with abrasive belt or chip removal) in order to speed up the production of pre-cut and beveled bars useful above all in the world of “white”.