VARO is today a benchmark for the production of special machines for wire processing. Its ability to conduct feasibility studies and create highly specialised machines is a unique opportunity for companies seeking customised solutions for their production needs.

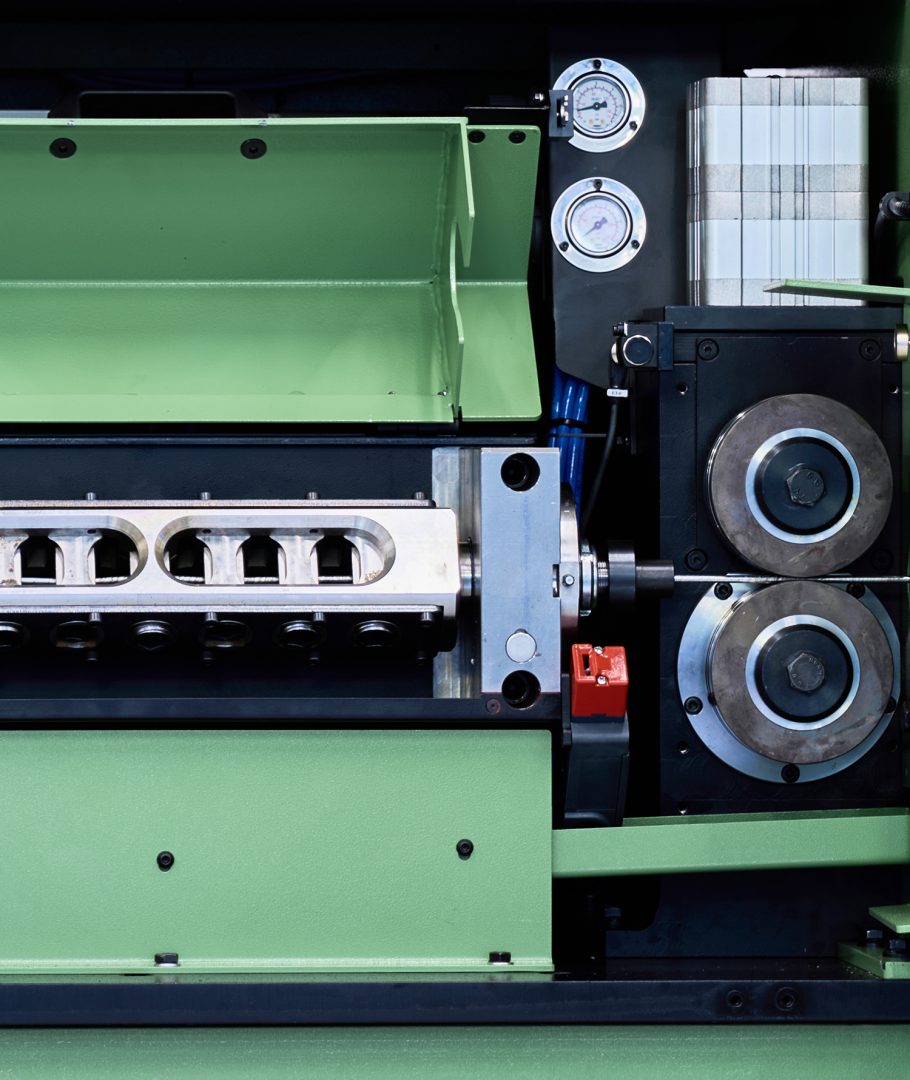

Precision and efficiency are essential elements in ensuring high-quality products and optimised production processes. In this context, VARO has established itself as a major player in the production of automatic wire processing machines, offering tailor-made solutions for a wide range of industrial applications. VARO has established itself internationally for the design and production of automatic welding and bending machines. However, what sets VARO apart is its ability to manufacture special machines, starting with a feasibility study for the production of customised and complex parts.

Feasibility study and creation of special machines

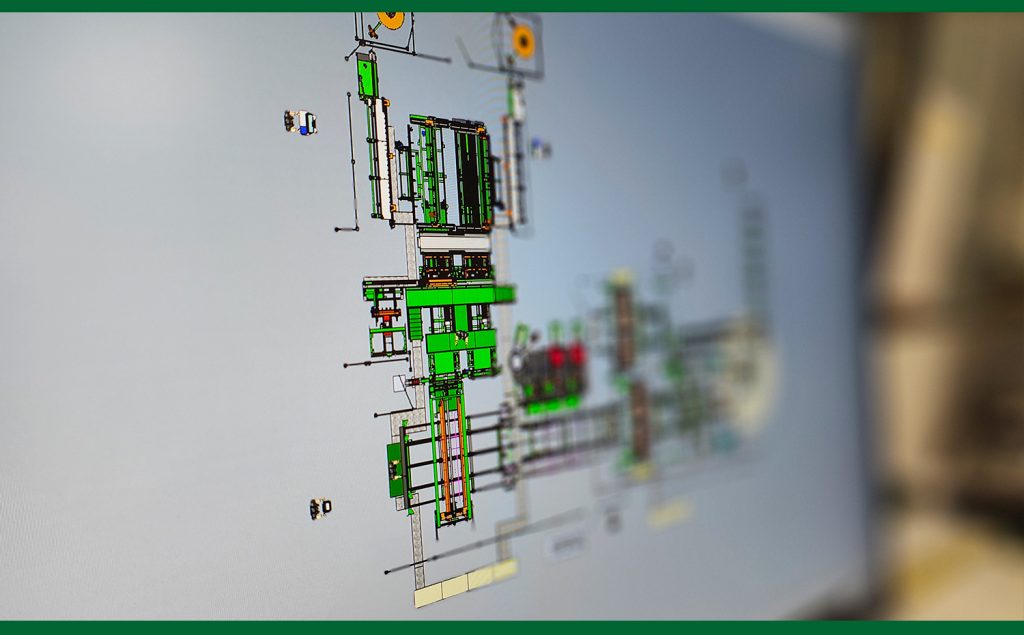

The production of special wire components can present unique challenges. Each industrial application has specific requirements, often requiring one-off parts or customised production. In this context, VARO’s expertise in feasibility studies becomes crucial. The process begins with a close collaboration with the customer to fully understand the needs and requirements of the project. VARO’s experts endeavour to analyse every detail, the technical specifications required, the production capacity needed and the budget constraints.

Once the initial analysis is complete, VARO’s team of highly qualified engineers and technicians implement a design plan that takes into account all the parameters identified in the feasibility study. This phase is crucial to developing a tailor-made solution that fully meets the customer’s needs.

Specialised expertise

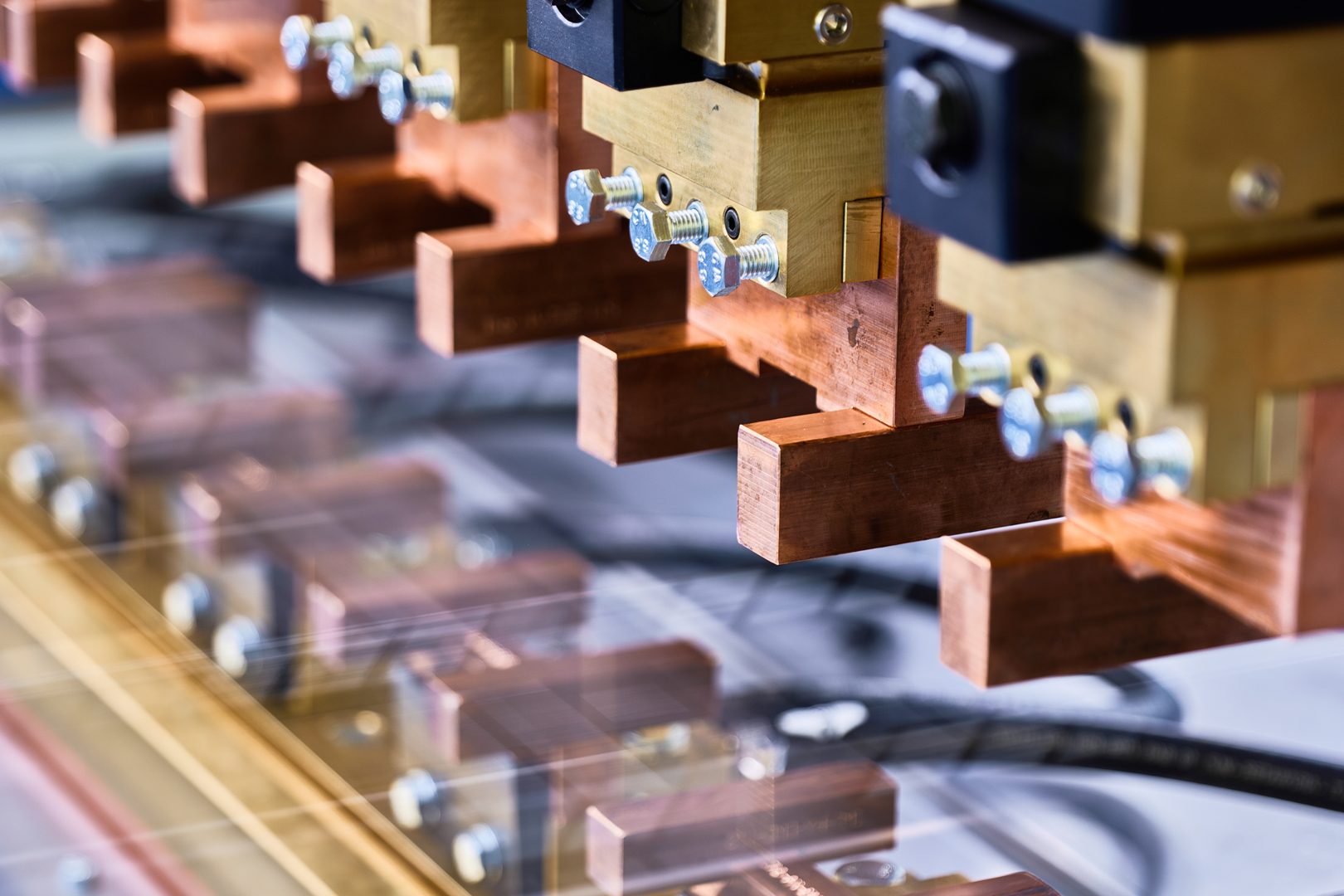

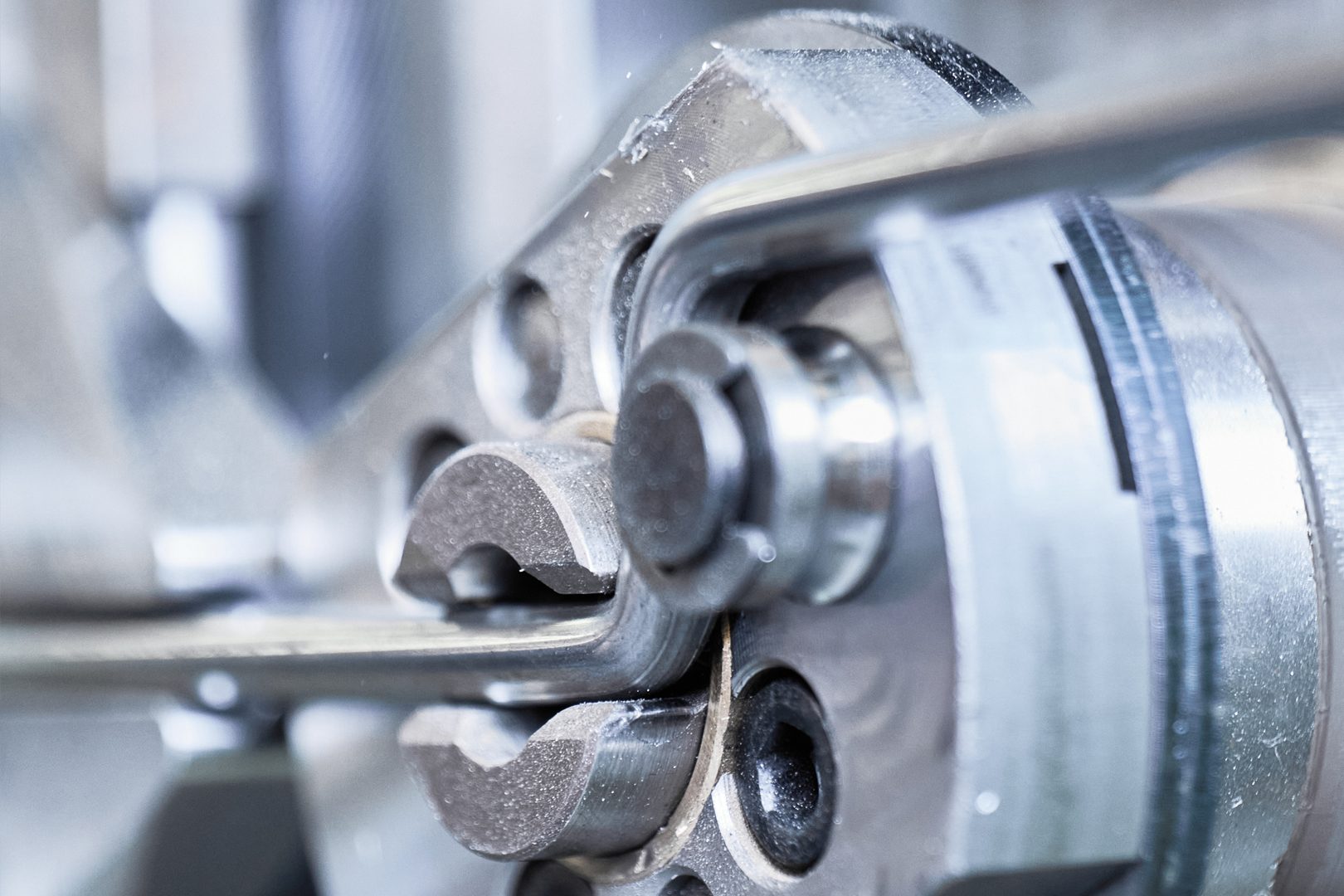

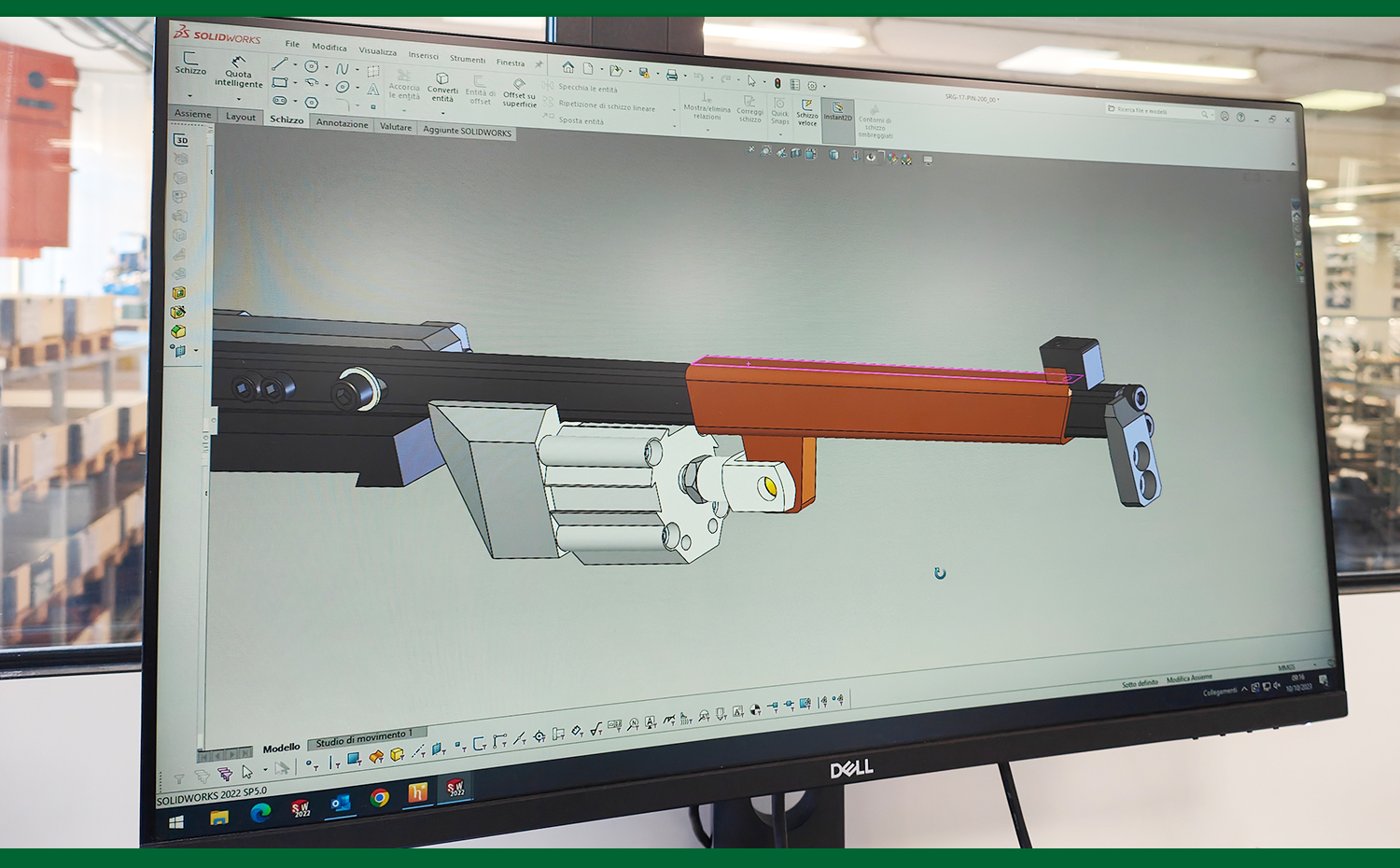

One of VARO’s distinguishing features is its ability to build special machines that can produce highly customised and complex parts. VARO’s team of engineers and technicians is highly specialised in the design and construction of customised machines that can perform highly complex welding, bending and wire processing operations.

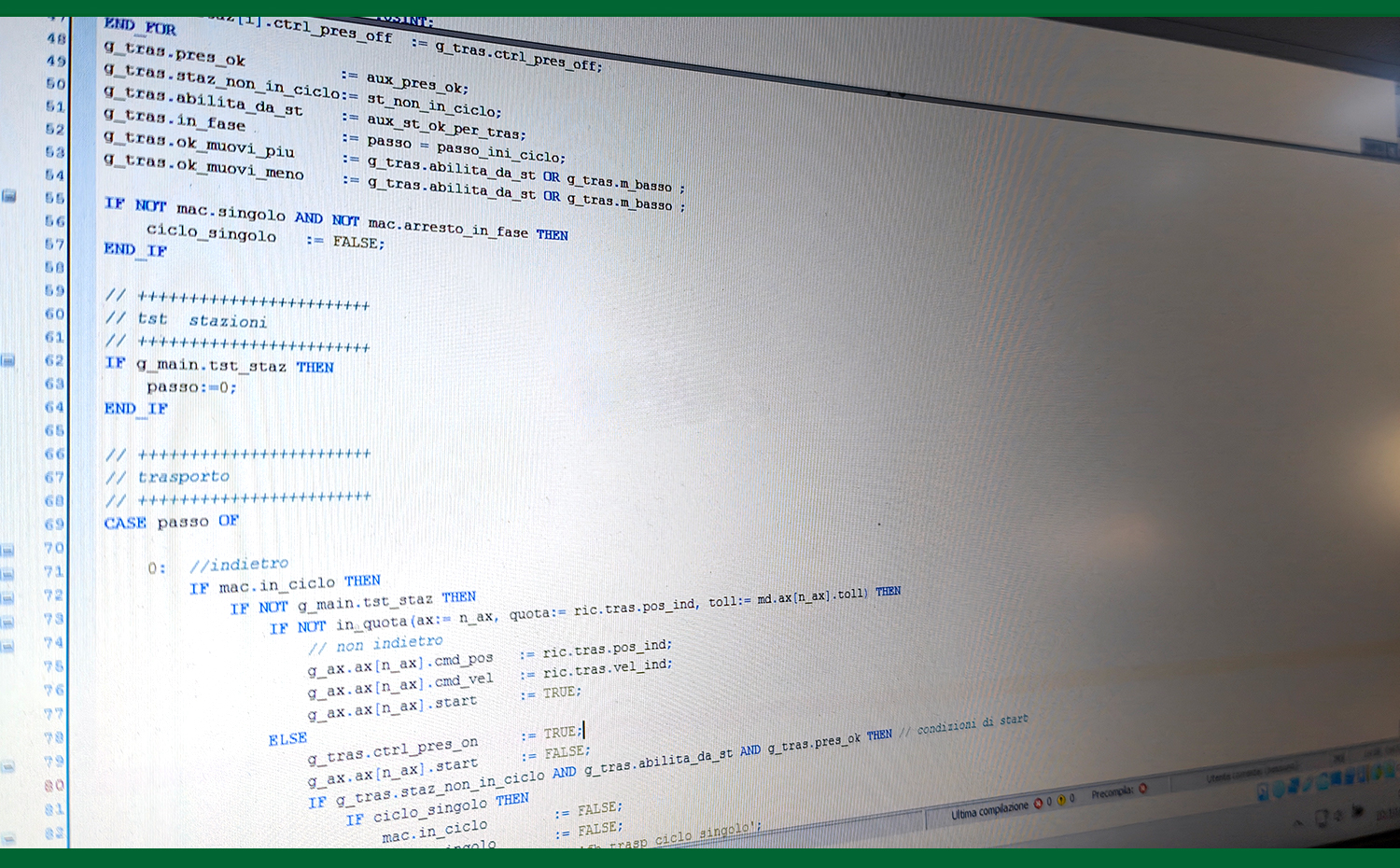

VARO has a wide range of technical expertise: mechanical design, electronic design, custom software programming as well as all the necessary skills for the construction of special machines that integrate these skills in a synergetic manner.

Once the initial analysis has been completed, VARO’s team of engineers and technicians puts in place a design plan that takes into account all the parameters identified in the feasibility study. This phase is crucial to developing a tailor-made solution that meets the customer’s needs flawlessly.

In synergy with the customer

Working with VARO for the production of wire objects or components offers numerous advantages. Firstly, customers benefit from VARO’s extensive experience in the sector, guaranteeing maximum precision and reliability in the production of customised parts. In addition, the customised solutions offered by VARO make it possible to optimise production processes and increase efficiency, reducing operating costs.

With a team of experts and a reputation for excellence in the industry, VARO works with companies around the world to manufacture special and innovative projects in wire processing.

We create tailor-made solutions to exactly meet specific production requirements: this approach has made us a leader in the creation of special machines for the production of special and complex products.