The year 2017 was a turning point for VARO, during which the lines of development for the next 5 years were drawn, characterised by investments, expansion of space, strengthening of the various departments and increase in production capacity.

From 2017 to 2022, VARO had a double digit growth, and this is the result of strategic choices that have brought about a marked change in the concept of made in VARO.

Strong internalisation of processes, expansion of space and investments in machinery and human resources were the focal points that determined the future results achieved by VARO.

New working environments for more and more modern production.

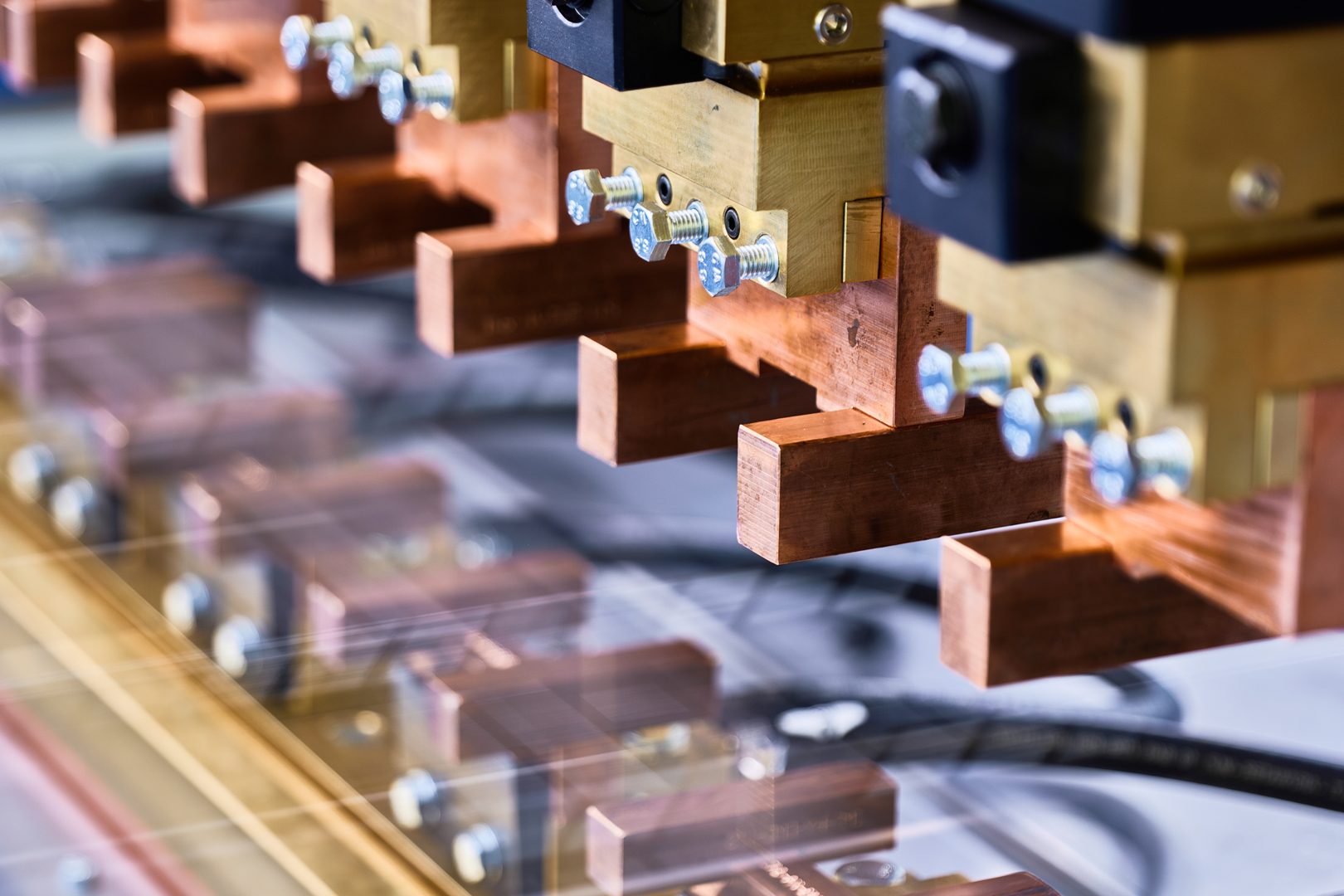

The creation of the VARO3 department, the production workshop for the creation of components for welding machines, bending machines, wire cutters, robotic islands and special lines was a major turning point in the process of creating VARO machines.

Starting in 2017, this department has been more than doubled in the course of 5 years and today 25 work centres are operational, all interconnected in logic 4.0, for better work planning and optimal stock management, both of the raw materials to be processed and of the parts produced, thus achieving greater efficiency and constant quality control.

The Painting Department has also been expanded and modernised, while the Carpentry Department has been upgraded with new state-of-the-art laser cutting and bending machines. The investments made have also made it possible to better plan production, managing activities in-house

More space for machines, more machines in testing.

The Assembly department has been expanded expanded several times during the five-year period 2017/2022, in order to increase the number of machines being tested at the same time. This expansion was also intended to respond to the new method of testing and setting up machines carried out in close collaboration with customers, which has lengthened the time the machines are at VARO, but has significantly reduced the time taken to install them at customers’ production sites.

These strategic choices have led to a considerable increase in VARO’s production capacity and have enabled the company to meet the growing demands of the market.

We are constantly looking for new solutions to improve our processes, to optimise them and increase efficiency.

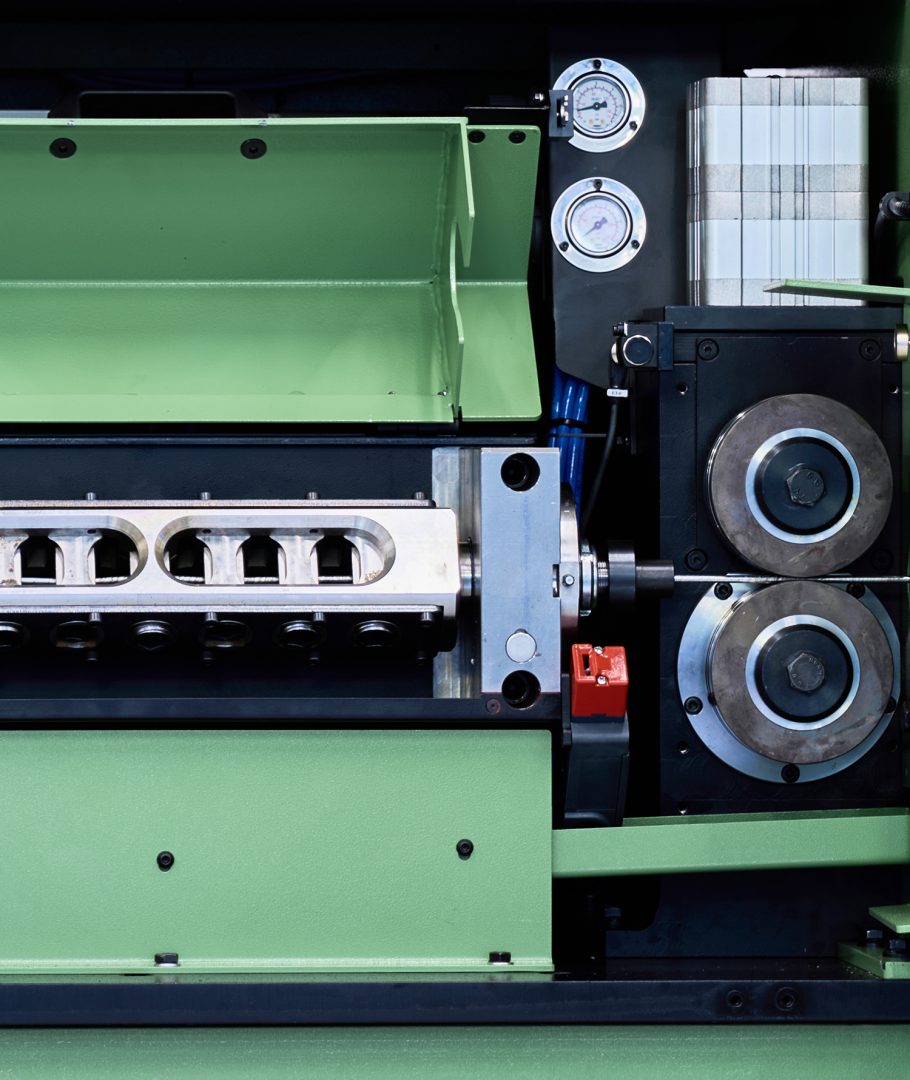

New departments dedicated to mass production: to be more and more competitive and efficient.

In the course of 2021, the TRF department, the first department dedicated to the series production of a VARO machine, was inaugurated in order to increase its production capacity as well as improve the quality control of the manufacturing processes.

This management model immediately brought excellent results from an organisational and operational point of view, convincing to replicate the model during 2022 for the series production of the most used machine modules.

Another process innovation that has improved VARO’s performance, contributing to the excellent results

Designing, R&D and development: more impetus for innovation.

VARO’s technical department is the heart of the company where ideas take shape. The addition of new specialised personnel has given new manpower to both the standard technical department and the research and development department, which specialises in the design of custom solutions and technical innovations.

Investments in research and development in particular have always been a constant in VARO’s way of doing things, and in the five-year period 2017/2022 it was crucial to boost innovation in order to modernise and optimise VARO machines

More training and cooperation with local institutes: VARO for young

VARO has also decisively invested in staff training to create the necessary skills for business development.

With this in mind, VARO for young took shape in 2021, a project set up to encourage young people to come to the company and experience the world of work first-hand.

In fact, VARO offers the possibility of curricular or extracurricular internships with flexible hours, thus enabling high school and university students to work during their studies, to put into practice what they are studying.

By making its experience available, VARO involves, trains and enthuses young people entering the world of work.

Acquisitions and a new corporate structure: ROTA Group and OMCG.

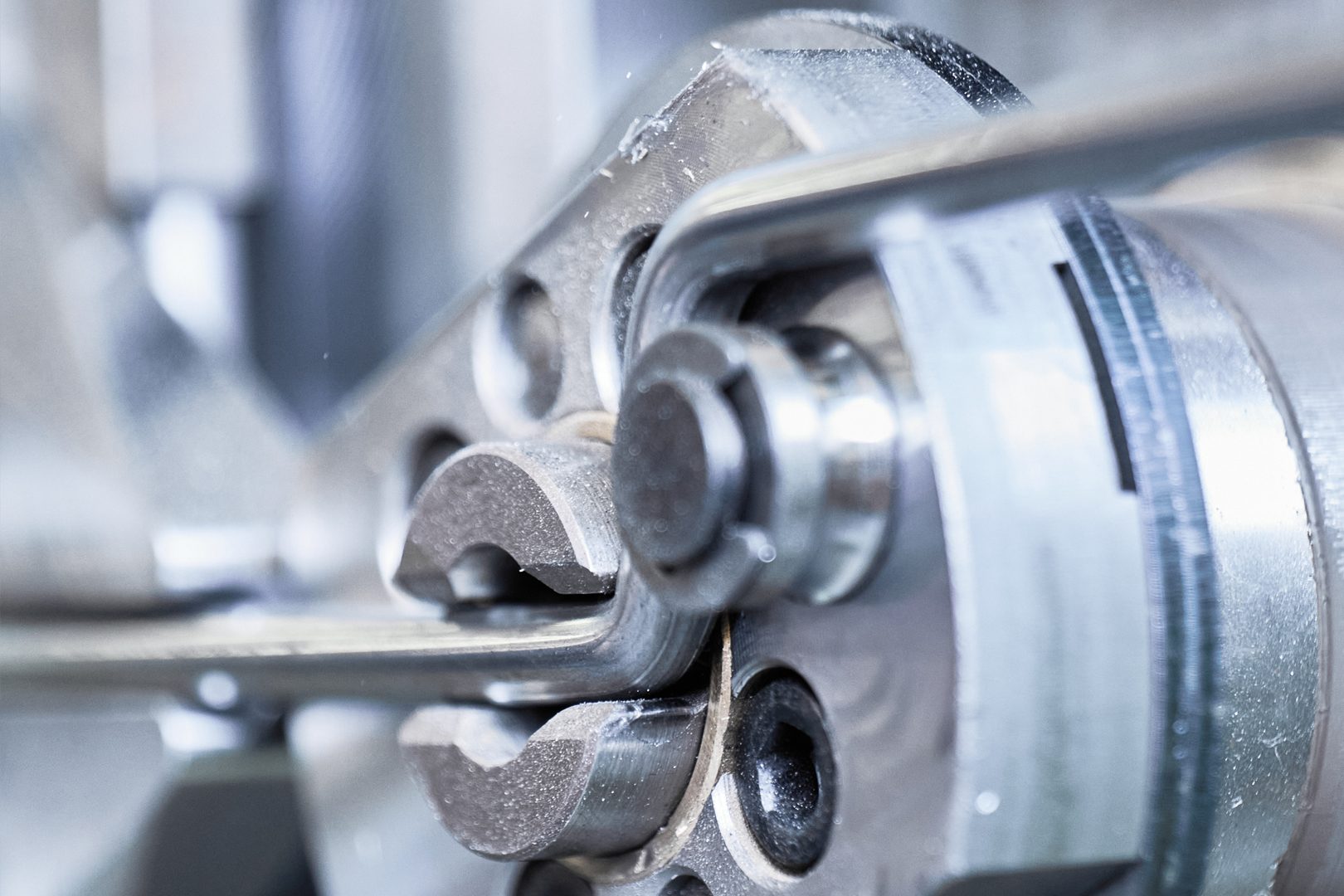

The Rota family, which has been leading VARO for over forty years, established the company ROTA Group in 2022 and finalised the acquisition of OMCG Italia, a company specialised in the design and production of CNC bending machines for wire, tube and strip metal parts.

The Rota family, on the strength of VARO’s market position gained over more than four decades of continuous research and development, took the decision to create ROTA Group and to proceed with the acquisition of OMCG Italia, an internationally established brand in the development of bending machines.

VARO and OMCG maintain their corporate identities and characteristics unchanged, but share know-how and technologies in order to improve each other and provide the market with increasingly high-performance automated wire processing solutions.

The strategic choices made in recent years have led to the achievement of important goals and have allowed us to grow, confirming our market position. We are proud of our team and of the results that we are all achieving together. The generational change that has been taking place for several years in many of VARO’s departments is going hand in hand with a modernisation of the industrial processes, management systems and technologies used, preserving the know-how built up in over 40 years of activity and evolving it.

We do not stop and our gaze is always looking to the future.

Marta Rota & Laura Rota