Industry 5.0 represents the latest frontier of industrial evolution, characterised by close collaboration between humans and intelligent machines.

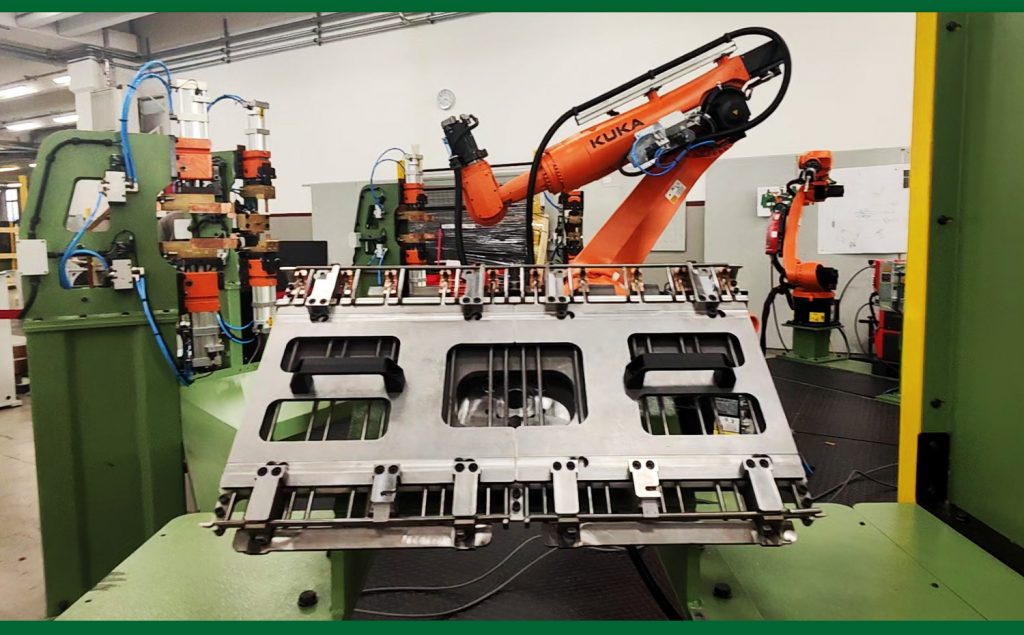

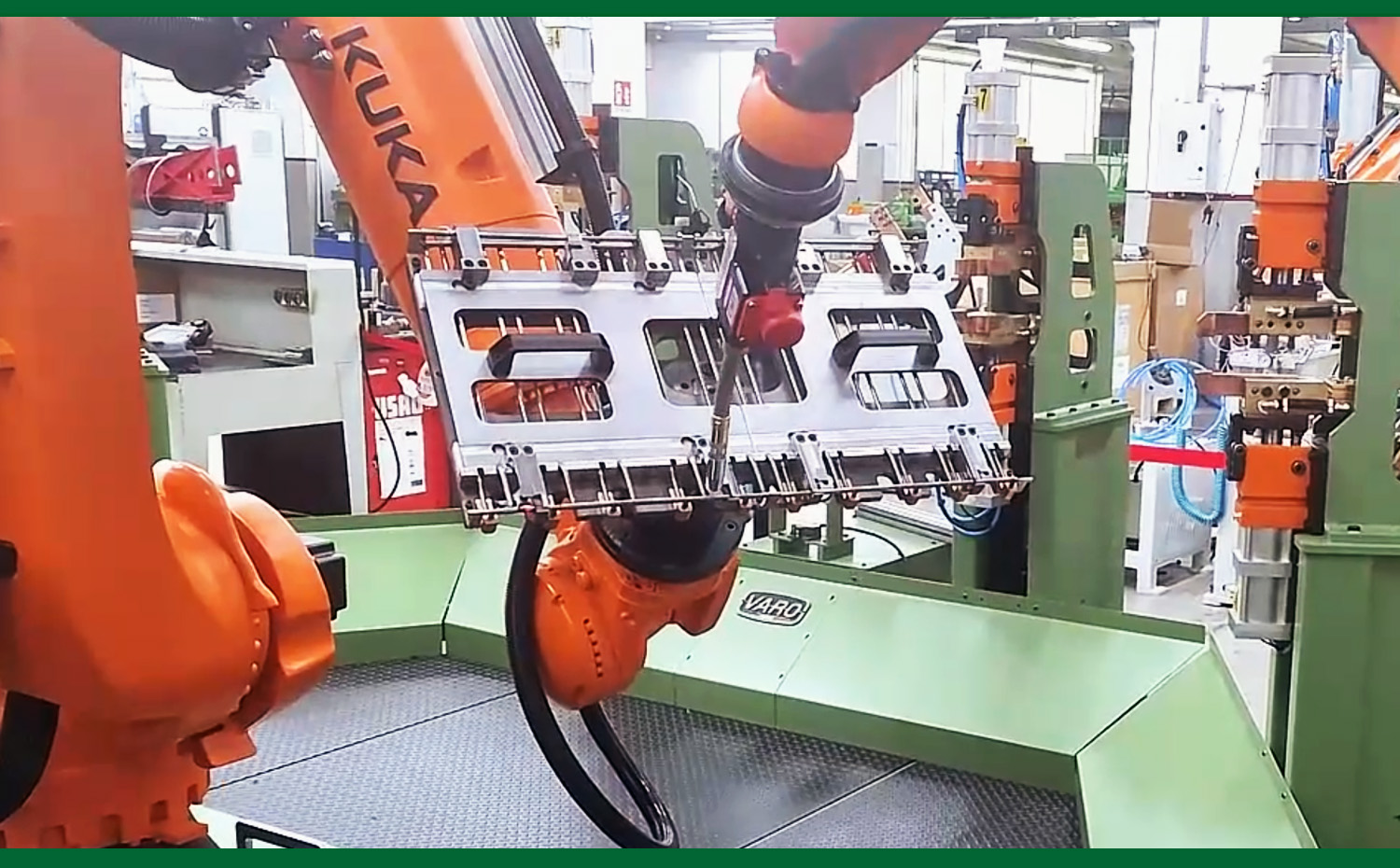

This new phase of industrial evolution goes beyond simple automation and seeks to integrate human skills with advanced technologies, creating a more efficient, flexible and intelligent working environment. In this context, the Robot Cell designed by VARO emerge as an excellent example of how human-machine collaboration is shaping the future of industries.

Industry 5.0: a holistic vision

Industry 5.0 aims to overcome the predominantly automated approach of Industry 4.0 by focusing on cooperation between human operators and automated systems. In this holistic vision, the aim is to improve flexibility and customisation in production, enabling people to make the most of their creative and decision-making skills, supported by advanced technologies.

Industry 5.0 and VARO Robot Cell

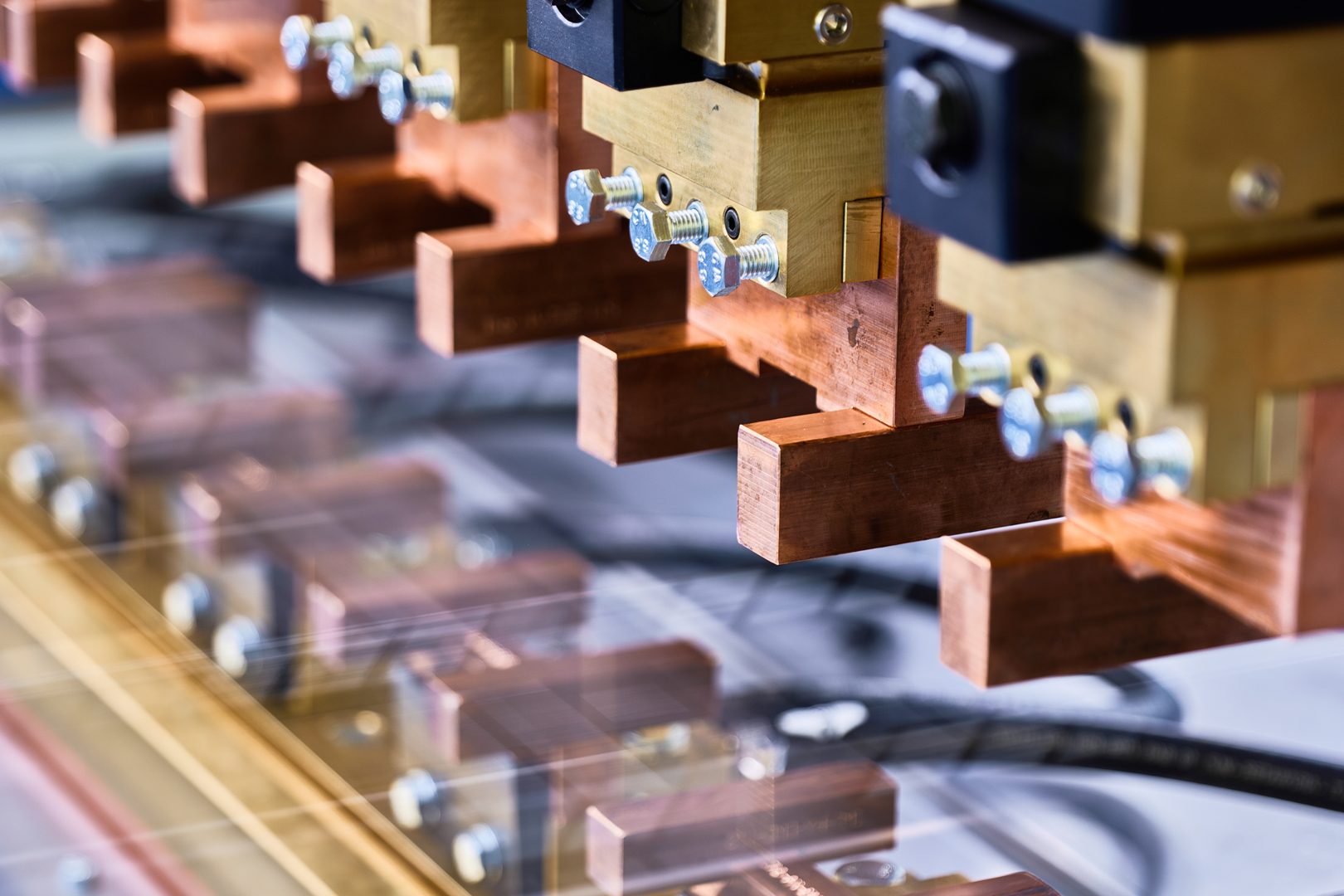

The Robot Cell developed by VARO represent a working environment in which robots and human workers collaborate synergistically to achieve common goals.

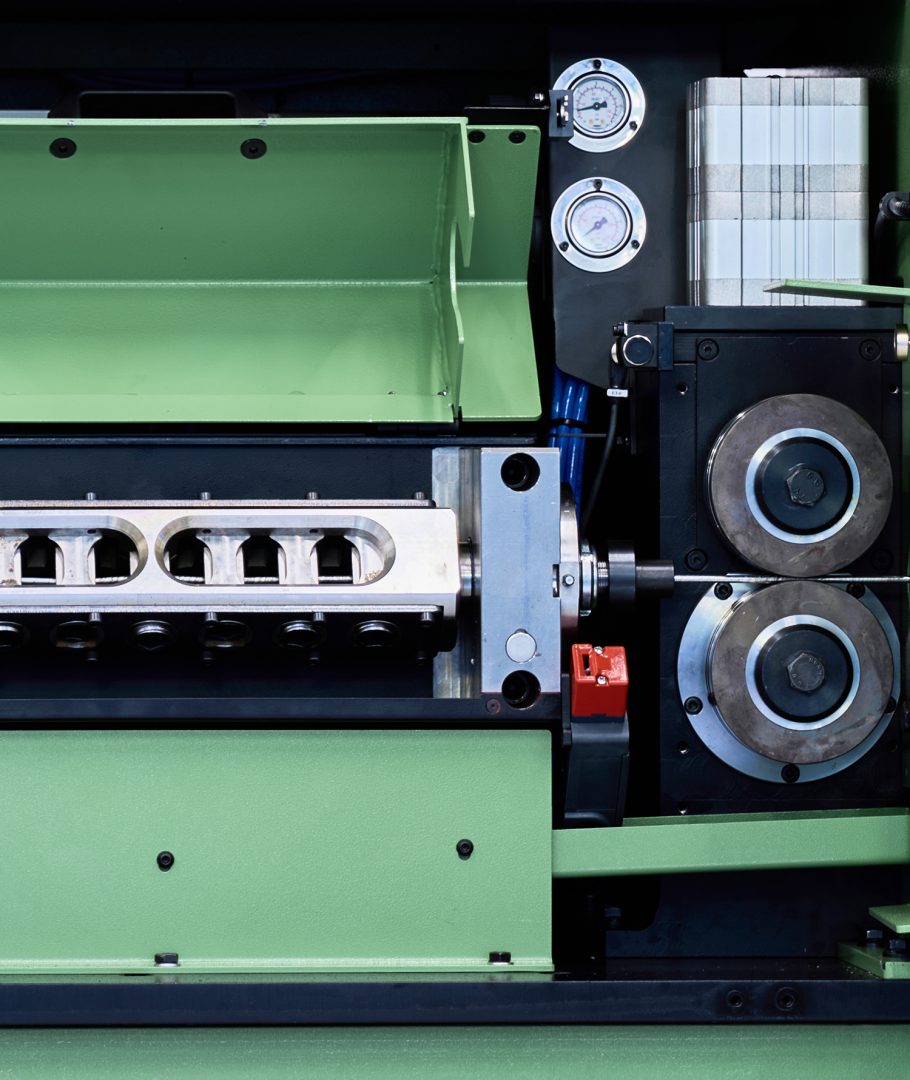

- Operational flexibility: VARO’s robot cell are designed to adapt quickly to changes in production. Robots can be easily reconfigured to perform new tasks, enabling highly flexible production.

- Intuitive human-machine interface: VARO has invested in the design of an intuitive human-machine interface (HMI), which allows human operators to easily interact with robotic systems. This makes collaboration more effective and reduces learning time.

- Safety and secure collaboration: safety is a priority in Robot Cell. Advanced sensors and vision systems enable robots to detect human presence and adapt their behaviour accordingly, ensuring a safe and collaborative working environment.

Benefits of human-machine collaboration

The human-machine collaboration promoted by VARO’s Robot Cells offers a number of significant benefits for companies and workers:

- Increased productivity: the synergy between robots and human workers leads to greater efficiency and speed in production.

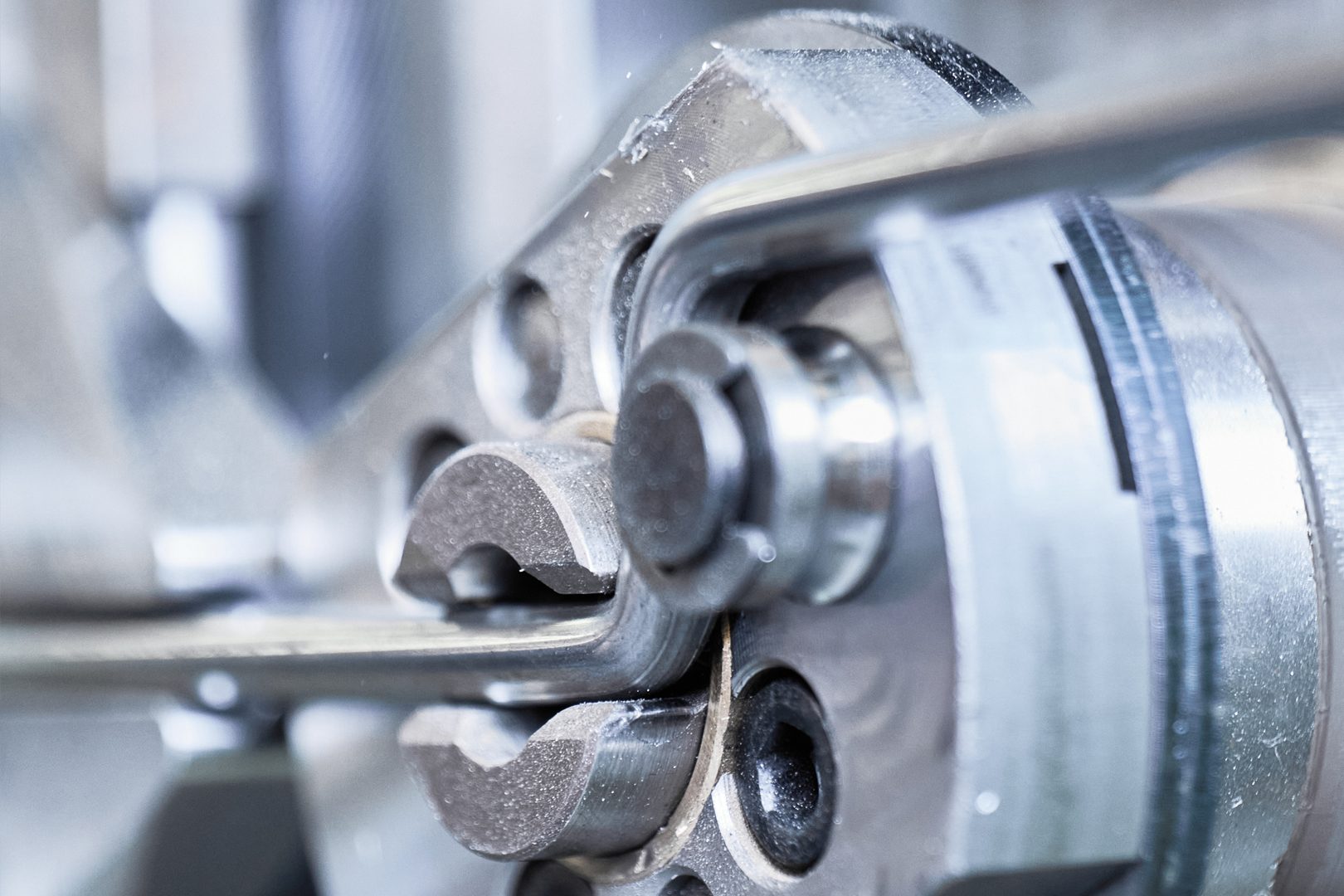

- Quality improvement: the precision of robots combined with human discernment helps to ensure higher product quality.

- Employment growth: contrary to the widespread fear of human replacement by machines, Industry 5.0 can lead to employment growth, as human skills are essential to drive and manage automated systems. Moreover, in robotic islands, the creation of complex components requires the use of manually loaded jigs, delegating the welding process to the automation of the robotic island: perfect human-machine cooperation.

- Adaptability to market changes: Robot Cells, thanks to their flexibility, allow companies to adapt quickly to changing market needs.

- Operational flexibility: VARO’s Robot cells are designed to adapt quickly to changes in production. Robots can be easily reconfigured to perform new tasks, enabling highly flexible production.

- Intuitive human-machine interface: VARO has invested in the design of an intuitive human-machine interface (HMI), which allows human operators to easily interact with robotic systems. This makes collaboration more effective and reduces learning time.

- Safety and secure collaboration: safety is a priority in Robot Cell. Advanced sensors and vision systems enable robots to detect human presence and adapt their behaviour accordingly, ensuring a safe and collaborative working environment.

Innovation, productivity, human-machine collaboration

VARO’s Robot cells are a concrete example of how the vision of Industry 5.0 is being translated into practical and innovative solutions: human-machine collaboration not only in theory, but in concrete applications that offer a promising future for industry.

The challenge now is to adopt and implement these technologies widely, fostering a culture of innovation and continuous learning in companies around the world. The road to Industry 5.0 is open, and VARO’s Robot Cells are a guide on this journey towards a smarter, more collaborative industrial future.