Thanks to our production process that it’s managed for the most part internally, we can give an immediate feedback to our customer’s requests.

The constant growth of the company in over 40 years of activity has been combined with the continuous and growing integration of the entire production process in-house, so as to ensure full control of quality and production times.

In contrast to the outsourcing of non-core manufacturing, over the years Varo has adopted a production model aimed at internalising processes, in order to have full control of the production process of a machine, thus guaranteeing a high level of quality standards and certain production times.

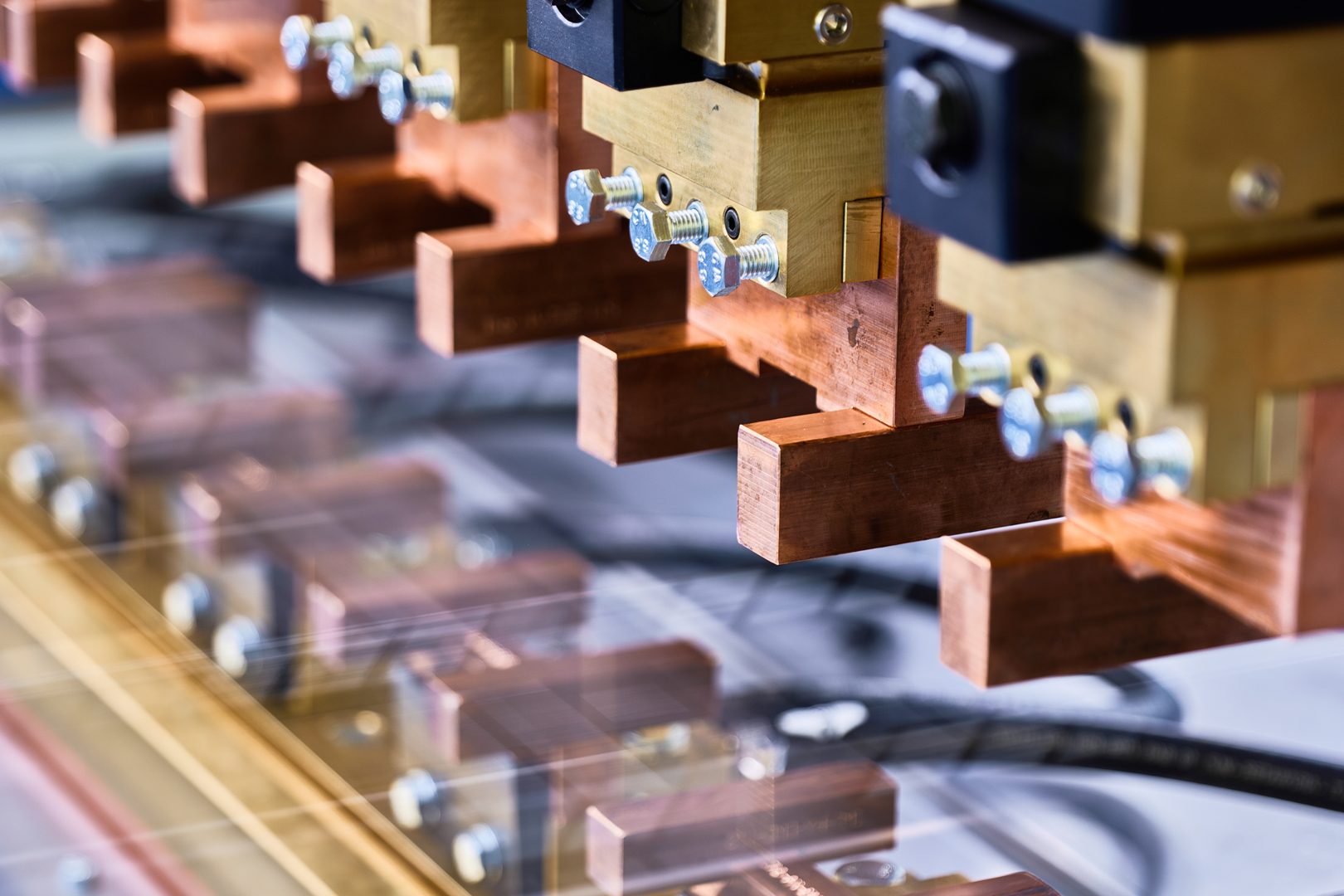

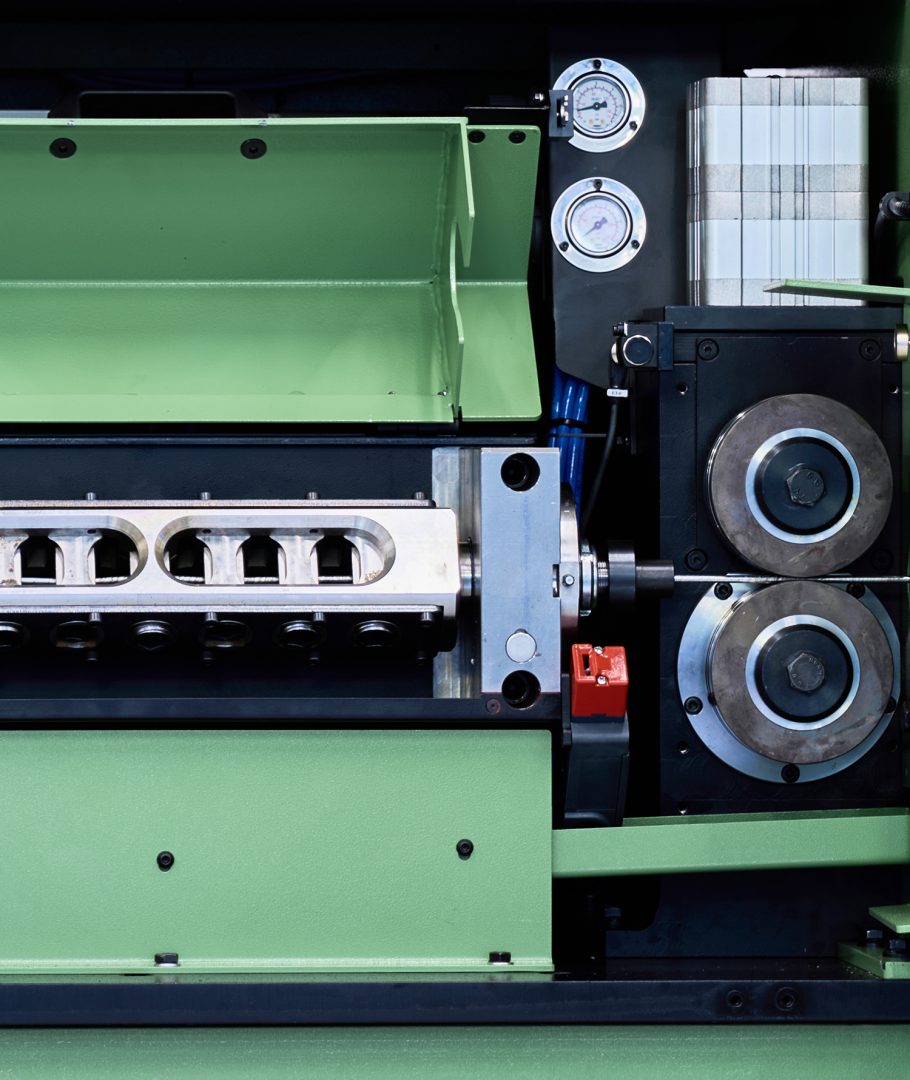

Our company structure guarantees continuity in production, since the process phases are managed by 13 departments. Each department has a manager and countless specializations: mechanical fitters, electricians, lathe turners, millers, warehouse workers, painters, software engineers.

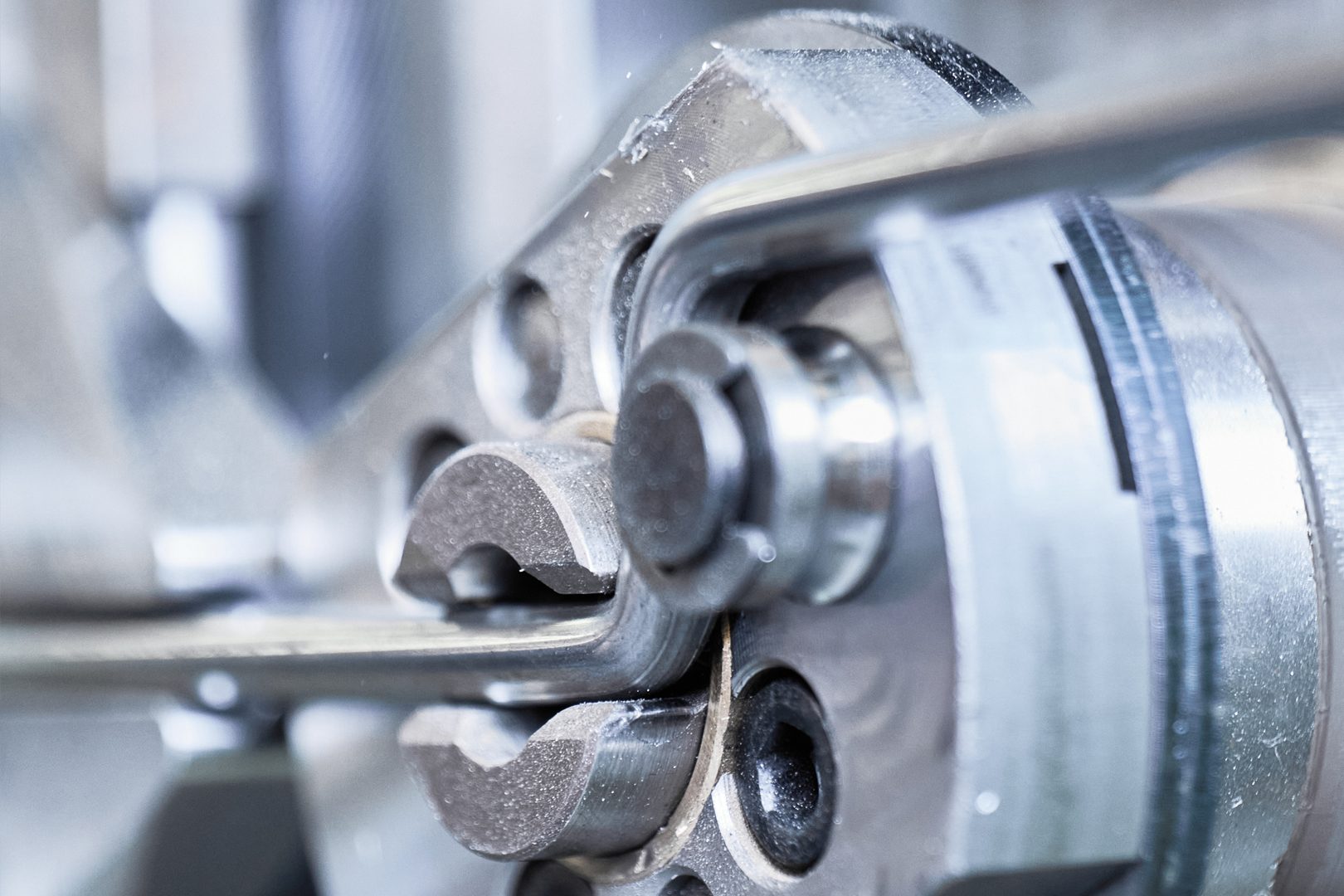

The experience gained over the years is exploited to manage a process flow that involves the different departments coordinating them in a dynamic and flexible way.

This organizational model ensures supply chain continuity, thanks to a short supply chain with as few steps as possible, to be faster, clearer and more predictable.

Each Varo department is independent but centrally coordinated and directly involved in the manufacturing of a machinery.